Over the years, the company has established a standard of astm 633c steel products pre-sale, in sale and after-sale service, which meets customers' needs in all aspects and in the whole process, so that our products and services are deeply trusted by customers, and has established a long-term cooperation and mutual benefit relationship with customers. The company adheres to astm 633c quality surpervision, comprehensively implements quality management, strictly controls the whole process of product from contract signing to after-sales service.

ASTM A441, used in low-tolerance, state-of-the-art structures, such as towers and large telescopes, astm 633c is a high-strength structural grade with a yield strength of 40,000 to 50,000 psi and an allowable bending stress of 24,000 to 30,000 psi.

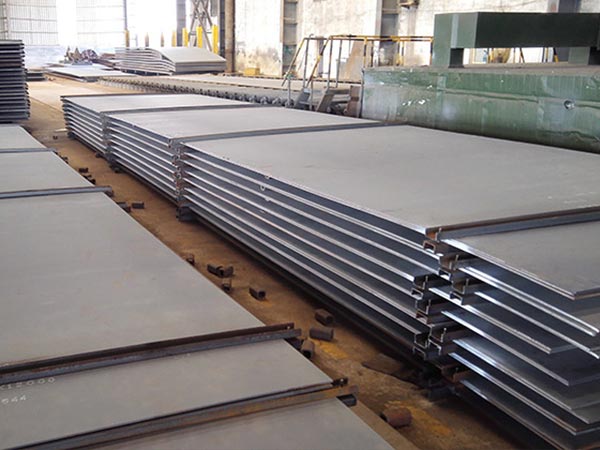

astm 633c, low alloy high strength steel can meet the requirements of various structures (such as large bridges, pressure vessels, ships, etc.) in engineering. At the same time, it is required to reduce the weight of the structure, improve the reliability and save materials and resources. Low alloy high strength steel is mainly used to manufacture various engineering structures with high strength requirements, such as bridges, ships, vehicles, high pressure vessels, oil and gas pipelines, large steel structures, etc. Because low alloy high strength steel can obtain high strength without complicated treatment process or even heat treatment, the quality of engineering structure is greatly reduced. Therefore, low alloy high strength steel is commonly used to replace the general carbon structural steel.

Laser cutting is that the horizontal laser beam emitted by the laser changes into a vertical downward laser beam through the 45° total reflector, and then focuses through the lens, forming a tiny spot at the focal point. When the spot hits the material, the material is heated to the vaporization temperature quickly, and evaporates to form a hole. With the movement of the beam on the material such as astm 633c, the auxiliary gas (carbon dioxide gas, oxygen, Nitrogen, etc.) blow away the melted slag, make the hole continuously form a very narrow width (such as about 0.1mm) cutting seam, and complete the cutting of materials.

13CrMo4-5 seamless pipe is a kind of pressure resistant seamless pipe in accordance with the European standard EN 10216-2. The chemical composition of 13CrMo4-5 seamless pipe is C 0.10-0.17, Si ≤ 0.35, Mn 0.40-0.70, P ≤ 0.025, S ≤ 0.020, Cr 0.70-1.15, Ni ≤ 0.30, Mo 0.40-0.60, Al ≤ 0.04, Cu ≤ 0.03. Mechanical properties of 13CrMo4-5 seamless pipe: tensile strength: 440-590 MPa, yield strength: ≥ 290 MPa, elongation: ≥ 22%, impact energy: ≥ 40J. astm 633c, 13CrMo4-5 seamless pipe is used in petroleum, chemical industry, power station, boiler and so on industries.

BBN steel strictly control quality of our carbon steel plate, alloy steel plates and structural steel plates. For astm 633c ASTM A572 Grade 50 structural steel plate, Our Q/C Department will inspect dimension before shipment, making sure structural steel plate thickness tolerance and width, length tolerance are matchable to the astm 633c standard requirements. The company is a good ASTM A572 Grade 50 structural steel plate supplier in the globle market and the head is located in China. Welcome to send us inquiry and questions about structural steel plate.

The company has passed the ISO9001: 2008 quality system certification, strictly implemented the ISO9001 quality management system. Besides, we have continuously improved the after-sales service network to make every effort to provide more convenient, accurate and faster services for all customers. We will supervise the production, control the quality in the factory, Inspect the cargo before shipment, Issue the test report to sales department. From the steel prodcution to steel delivery, we always focus the whole process.

Leave A Comment