Zhengzhou BBN steel company was established in 2000. After more than ten years of development, it has formed a professional operation pattern integrating R&D, production, sales and after-sales service. In recent years, SA573 Grade 70 steel for marine engineering based on a high starting point and high technology, the company has vigorously developed various steel products SA573 Grade 70 steel for marine engineering and deep-processed parts, steel structures, precision castings, seamless pipes.

EN 10083/3-2006 42crmo4 is an industrial material. 42CrMo4 is used to manufacture forgings that require higher strength and larger quenched and tempered section than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips that are heavily loaded. 42CrMo4 is also It can be used for oil deep well drill pipe joints and fishing tools under 2000m.

Weathering steel is made of ordinary carbon steel with a small amount of copper, nickel and other corrosion-resistant elements. It has the characteristics of high-quality steel, such as strength, toughness, ductility, forming, welding and cutting, abrasion, high temperature, fatigue and so on. The weathering resistance of weathering steel is 2-8 times of that of plain carbon steel SA573 Grade 70 steel for marine engineering, and the coating property is 1.5-10 times of that of plain carbon steel. Weathering steel has the characteristics of rust resistance, corrosion resistance, life extension, thinning and consumption reduction, labor saving and energy saving, etc..

SA573 Grade 70 steel for marine engineering, Hot rolled seamless tube is usually produced on automatic tube rolling mill. After the solid tube blank is inspected and the surface defects are removed, it is cut to the required length, centered on the end face of the piercing end of the tube blank, then sent to the heating furnace for heating, and perforated on the piercing machine.

EN10025-6 S960QL structural steel plates are quenched and tempered high strength steel with yield strength of 590Mpa ~ 960MPa. SA573 Grade 70 steel for marine engineering, S960QL steel plates have technical requirement of flaw detection, Z15 Z35 thickness direction performance requirements, high strength and high toughness requirements and so on.

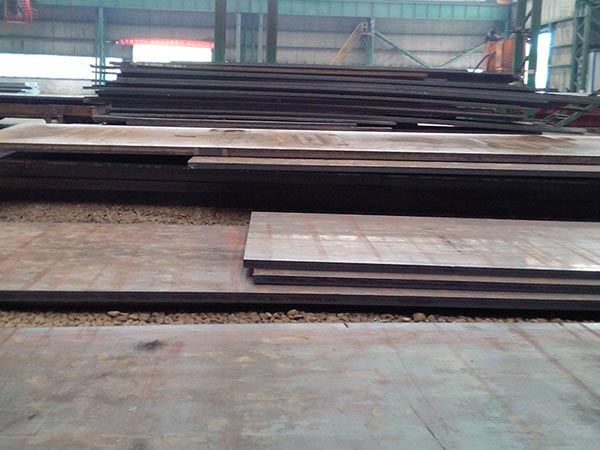

BBN steel strictly control quality of our carbon steel plate, alloy steel plates and structural steel plates. For SA573 Grade 70 steel for marine engineering ASTM A572 Grade 50 structural steel plate, Our Q/C Department will inspect dimension before shipment, making sure structural steel plate thickness tolerance and width, length tolerance are matchable to the SA573 Grade 70 steel for marine engineering standard requirements. The company is a good ASTM A572 Grade 50 structural steel plate supplier in the globle market and the head is located in China. Welcome to send us inquiry and questions about structural steel plate.

After-sales service is an important part of measuring a product good or not. After sales service can't be ignored. Good service can really make consumers feel relieved. We have always done a good job in after-sales service, so as to bring consumers a better reference when purchasing and a better experience during use of our steel materials. We will call back and follow up the performance of our steel products regularly.

Leave A Comment