BEBON Iron & Steel has fully passed the ISO9001 quality system certification, marine steel has passed 9 countries' classification societies, and construction steel has obtained the CE Lloyd's CE Mark certification. The main body of a633 grad

BEBON Iron & Steel has fully passed the ISO9001 quality system certification, marine steel has passed 9 countries' classification societies, and construction steel has obtained the CE Lloyd's CE Mark certification. The main body of a633 grad

BEBON Iron & Steel has fully passed the ISO9001 quality system certification, marine steel has passed 9 countries' classification societies, and construction steel has obtained the CE Lloyd's CE Mark certification. The main body of a633 grade e ultimate strength steel passed ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification. The main a633 grade e ultimate strength production processes and technical equipment of the enterprise have reached the international advanced level, the comprehensive competitiveness has entered the international advanced ranks, and the international influence has been significantly enhanced.

ASTM A387 steel is the standard specification for pressure vessel plates, alloy steel, chromium-molybdenum. Plates under this standard Hebei Metals supplies include ASTM A387 Grades 2, a633 grade e ultimate strength Grade 12, Grade 11, Grade 22, Grade 22L, Grade 21, Grade 21L, Grade 5, Grade 9, Grade 91. Each grade except Grades 21L, 22L, and 91 is available in two classes of tensile strength levels. These Cr-Mo A387 alloy steel is primarily manufactured for welded boilers and pressure vessels for elevated temperature service.

The excellent properties of wear resistant steel plate meet the strict requirements of high strength, high wear resistance, stability, straightness and surface quality. The combination of high hardness, high strength and excellent impact toughness makes a633 grade e ultimate strength plate become an ideal material for a wide range of applications. The production thickness of wear resistant steel plate is generally between 8-100mm.

In order to obtain the seamless tube with smaller size and better quality, the method of cold rolling, cold drawing or the combination of the two must be used. Cold rolling is usually carried out on a two high mill, and a633 grade e ultimate strength pipes are rolled in a circular pass composed of a variable cross-section circular groove and a fixed conical head. Cold drawing is usually carried out on single chain or double chain cold drawing machines of 0.5-100t.

20# seamless steel pipe chemical composition: C: 0.07-0.23, Si: 0.17-0.37, Mn: 0.35-0.65, Cr: 0.25, Ni: 0.30, Cu: 0.25. 20# seamless steel pipe mechanical properties: recommended heat treatment temperature: 910℃, tensile strength: 410 MPa, yield strength: 245 MPa, elongation: 25%, impact energy is not required. 20# seamless steel pipe hardness is higher than 10# seamless steel pipe. a633 grade e ultimate strength, 20# seamless steel pipe has good weldability, no temper brittleness, and its machinability can be improved by water quenching. 20# seamless steel pipe can be used to make welded components, as well as parts with small load after forging, hot stamping and cutting.

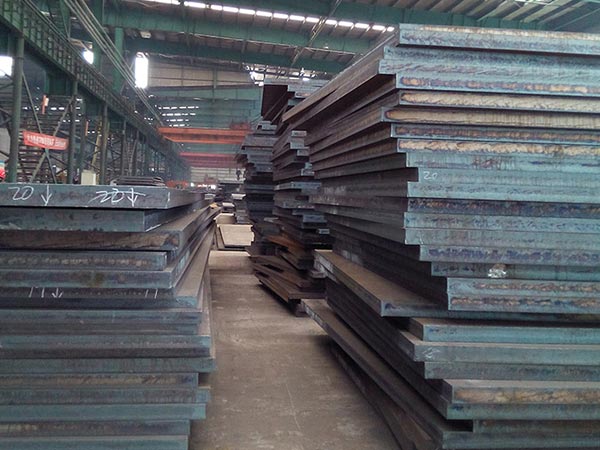

The company is mainly engaged in a633 grade e ultimate strength steel plates manufacturing and deep processing, sales and distribution. It is committed to building a complete modern steel purchase and sale network. Here we would like to express our sincere gratitude to our old and new friends who have always given care, support, affirmation and help, and sincerely hope to establish a long-term cooperative relationship with them for mutual benefit, win-win and common development, and work a633 grade e ultimate strength together for a better tomorrow.

We should focus on the main problems to be solved and pay attention to efficiency. After receiving the user's quality objection report data, the possible causes, responsible units, compensation amount, etc. of the problem shall be judged based on experience. To have a clear service plan, to be clear about what your main problem is, what technical support is needed, these should be prepared.

Leave A Comment