The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system

The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system

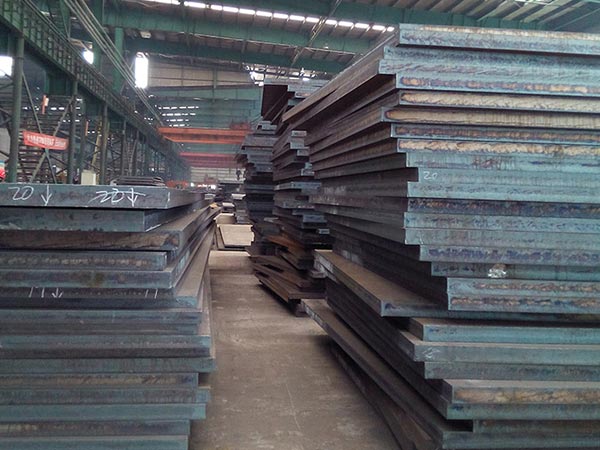

The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system and high-quality team are the core competitiveness of the company. The company will continue to provide customers with A573 Grade 65 hot rolled plate steel density high-quality, timely and perfect steel products and services under the guidance of the mission of "striving for perfection to meet customer needs".

S45C steel plate chemical composition: C 0.42~0.48, Si 0.15~0.35, Mn 0.60~0.90, P≤0.030, S≤0.035, Cu≤0.30, Ni≤0.20, Cr≤0.20Mechanical properties of A573 Grade 65 hot rolled plate steel density productTensile strength>686MPaYield strength>490MPaElongation δ5>17%Shrinkage ψ>45%Impact toughness value>78J/cm2The hardness is 201~269HB.

The steel plate and strip after hot rolling treatment are generally called hot rolled plate. Compared with other steel plate processing industries, A573 Grade 65 hot rolled plate steel density, hot rolled plate has these characteristics. First, low hardness, easy processing. Compared with other steel needs special mechanical equipment, hot rolled plate is a very convenient for processing. Second, good ductility, not easy to break, good compression capacity, long service life. Third, the manufacturing process is simple, and the price and cost are relatively cheap compared with other steels.

Different from A573 Grade 65 hot rolled plate steel density, the alloy wear-resistant layer of alloy plate is mainly chromium alloy, and other alloy components such as manganese, molybdenum, niobium, nickel are also added. The carbides in the metallurgical structure are distributed in a fibrous shape, and the fiber direction is perpendicular to the surface. Carbide microhardness can reach HV1700-2000 and surface hardness can reach HRC58-62. Alloy carbides have strong stability at high temperatures, maintain high hardness, and also have good anti-oxidation properties. They are fully used within 500°C.

The chemical composition difference between A573 Grade 65 hot rolled plate steel density, Q235B and 20# steel is as follows: The chemical composition of 20# steel: C: 0.17-0.23%, Si: 0.17-0.37%, Mn: 0.35-0.65%, Cr: ≤ 0.25%, Ni: ≤ 0.30%, Cu: ≤ 0.25%. Chemical composition of Q235B steel: C: ≤ 0.20%, Si: ≤ 0.35%, Mn: ≤ 1.40%, P: ≤ 0.045%, S: ≤ 0.045%. The difference of mechanical properties between A573 Grade 65 hot rolled plate steel density, Q235B and 20# steel is as follows: The mechanical properties of 20# steel: tensile strength 410 MPa; yield strength 245 MPa; elongation after fracture: 25; reduction of area: 55; no impact. Q235B steel mechanical properties: tensile strength 370-500 Mpa; yield strength: ≥ 235 Mpa; elongation after fracture: 25; impact absorption energy: 27J.

S355J2 hot rolled steel plate executive standard: EN10025-2S355J2 hot rolled steel plate delivery status: control binding, normalizing rolling, normalizingThe European standard S355J2 hot rolled steel plate is available from A573 Grade 65 hot rolled plate steel density stock and can be cut and processed according to the requirements of customers; the futures can be produced according to your requirements, and our S355J2 hot rolled steel plate price is preferential and the delivery time is fast, welcome to contact and purchase.

After sales service support personnel pay attention to commitment in their work. In the process of people to people communication, mutual trust is an important factor for the long-term and stable communication. After sales service personnel must do what they say in the process of communication with customers.

Leave A Comment