The quality inspection department is responsible for the inspection management of raw materials and finished products, and the quality inspection and acceptance of products and raw materials. Strictly abide by the company's management system, conscientiously exercise the management power given by the company, and put an end to all ultra vires; be responsible for the inspection of all kinds of raw materials entering the company, and put forward quality problems and handling opinions.

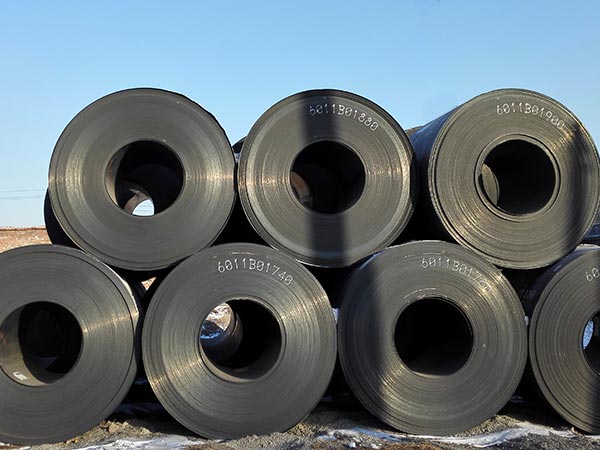

A573 Grade 70 steel for storage tanks, low alloy high strength steel has good weldability. Welding is the most common method to construct engineering structure, so the steel used in engineering structure requires good welding performance. Low alloy high strength steel has low carbon content, low alloy element content and good plasticity, so it is not easy to produce quenching structure and crack in the weld area, and the addition of Ti, Nb, V can also inhibit the grain growth in the weld area. Therefore, most of the low alloy high strength steels have excellent welding performance and no heat treatment is required after welding.

ASTM A333 Grade 6 pipe A573 Grade 70 steel for storage tanks for low temperature services at above -45℃.Pipe Sizes: 1/8” to 24”Wall thickness Schedules: SCH 10, SCH 20, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160, SCH XXSLength: Single Random Length, Double Random Length, 20 ft, 40 ftEnds Types: Plain, BeveledCoatings: 3PE/3LPE, FBE, Galvanized, Varnished, CRA or stainless clad and lined

If customers have any difficult problems during use of the steel materials, they can contact the company's after-sales service department to feedback the existing problems. The after-sales department will reply as soon as possible to ensure that each customer has a good after-sales experience. Under special circumstances, the after-sales service department will start the problem-solving process, and the engineers in charge of the area will quickly follow up to solve the problem.

Leave A Comment