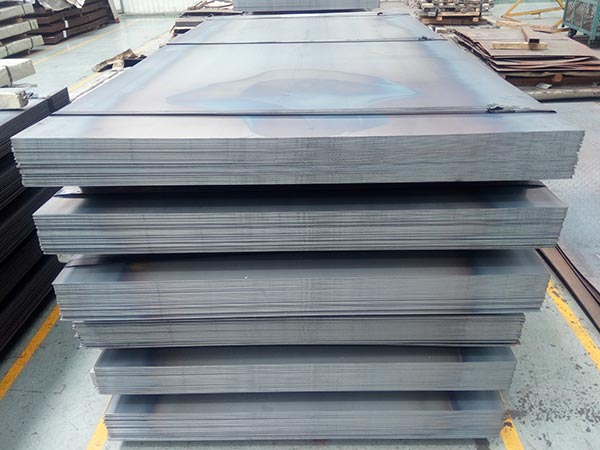

The company is committed to providing customers with high-quality and low-cost SA573 Grade 65 specification steel products as the goal, striving to create value for customers as its own responsibility. With advanced Kaiping processing equipment and strong logistics distribution system, the company can meet the needs of customers at any time. The company has the advantages of SA573 Grade 65 specification complete specifications, low price and fast distribution, With the service concept of keeping promise and valuing quality, it has won the trust and unanimous praise of the majority of users. The scale and strength of the enterprise is in the forefront of domestic metal material business units.

The seamless carbon steel pipe for ships (gb5213-85) is the seamless carbon steel pipe for the manufacture of class I pressure pipe system, class II pressure pipe system, boiler and Superheater of ships. SA573 Grade 65 specification. The working temperature of carbon steel seamless pipe wall shall not exceed 450 ℃, and that of alloy steel seamless pipe wall shall exceed 450 ℃.

The weldability of SA573 Grade 65 specification is good. It means that under certain process and construction conditions, SA573 Grade 65 specification can obtain good performance after welding. Weldability is a measure of the hot workability of steel. Weldability can be divided into weldability in construction and weldability in use. Weldability in construction refers to the sensitivity of cracking in weld metal and near seam zone, and hardening sensitivity of steel in near seam zone. Good weldability means that under certain welding process conditions, the weld metal and steel near the seam do not produce cracks. Weldability in use means that the mechanical properties of weld and HAZ steel are not lower than those of base metal.

After adding trace elements such as phosphorus, copper, chromium, and nickel to Q355NH steel, a dense and highly adherent protective film is formed on the surface of the weathering steel, which prevents rust from spreading and developing, and protects the substrate under the rust layer to slow its corrosion . An amorphous spinel oxide layer of about 50 μm to 100 μm thick formed between the rust layer and the substrate is dense and has good adhesion to the base metal, which greatly improves the atmospheric corrosion resistance of the steel material, SA573 Grade 65 specification.

SA573 Grade 65 specification, St52-3 steel is a low alloy, high strength structural steel which can be readily welded to other weldable steel. St52-3 steel’s mechanical properties is yield strength more than 355 MPa, tensile strength 490-630Mpa. For St52-3 steel, the C element content is 0.24%, the Si element content is 0.55% max, the Mn element content is 1.60% max, the P element content is 0.045% max, the S element content is 0.045% max.

We have a professional production team and high-quality production equipment, and we also have a great SA573 Grade 65 specification advantage in price, with its own factory, large-scale production to reduce the price. Strictly control each production line to ensure the SA573 Grade 65 specification production of high-quality steel plates, steel pipes and other products that meet customer requirements.

The after-sales service department will pay return visit to each customer by call or email, report problems found during the return visit in time, and discuss with the production and quality inspection center to propose effective solutions and follow up in a timely manner, so as to ensure the benefits each customer are fully guaranteed, and to provide customers with more value-added services.

Leave A Comment