The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system

The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system

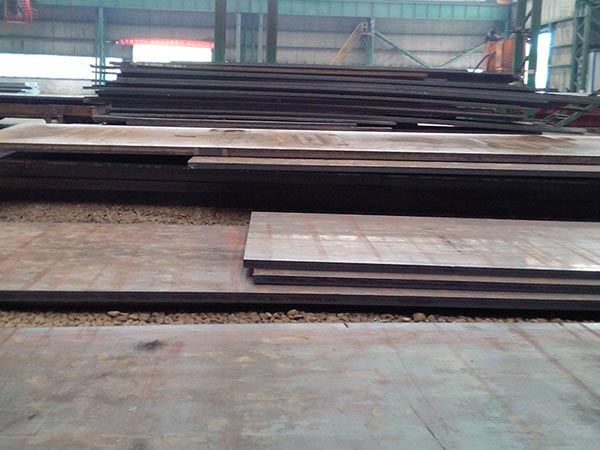

The company adheres to the people-oriented concept and takes "learning, sharing, gratitude, integrity, respect and responsibility" as the enterprise values. Advanced equipment, scientific standardized management, strict quality assurance system and high-quality team are the core competitiveness of the company. The company will continue to provide customers with A573gr.65 inspection high-quality, timely and perfect steel products and services under the guidance of the mission of "striving for perfection to meet customer needs".

NM500A is the wear-resistant steel grade of BBN STEEL Plant, with a thickness between 8mm and 150mm. NM500A wear-resistant steel is used in construction machinery, mining machinery, coal mining machinery, environmental protection machinery, metallurgical machinery and other manufacturing enterprises. It is mainly to provide protection in the occasions or parts that require wear resistance, so that the equipment life is longer, and the maintenance shutdown caused by maintenance is reduced, and the capital investment is correspondingly reduced.

Hot-rolled coil is a commonly used steel product in the industry. It has a relatively wide variety of products and a wide range of uses. A573gr.65 inspection, Hot-rolled coils are widely used in related industries such as petrochemical equipment, automobiles and bridges. Hot-rolled coils are also used in machinery industries such as ships and automobiles because of their good toughness and relatively high strength.

When the stainless steel plate is alloyed with chromium, the type of surface oxide is changed to that formed on pure chromium metal. This tightly adherent chromium rich oxide protects the surface from further oxidation. This kind of oxide layer is very thin, through which we can see the natural luster of the steel surface, so that A573gr.65 inspection, stainless steel has a unique surface.

A573gr.65 inspection, API 5L X52 steel with the thickness range is 1.2-40mm, the width range is 1220-4200mm, and the length range is 5000-18000mm. API 5L X52 steel’s mechanical properties is the yield strength 300MPa, and the tensile strength 460MPa. To be specified in details: Maximum content for C≤0.28%, Mn≤1.4%, P≤0.030%, S is 0.030%, V+Nb+Ti≤0.15%, Copper maximum is 0.50%, nickel maximum 0.50%, chromium 0.50%, Molybdenum 0.15%.

The high strength A573gr.65 inspection low alloy steel, which is shorten as HSLA steel, is one of our main products. We have professional team to serve you. For any demands or questions about HSLA steel, for example, ASTM A572 grade 50 chemical composition, difference between S355JR and S355J2, mechanical properties of A573gr.65 inspection ST52 steel, Q345B tensile strength, Q345D steel ASTM equivalent, HSLA steel price etc. , please do not hesitate to contact us and consult.

The company adopts one-to-one fast service and has formed a professional after-sales service team to deal with various problems reflected by customers as soon as possible. At the same time, a traceable product traceability system has been established. It has always been placed at an important core position to resolve customer worries. Our steel A573gr.65 inspection products are always committed to “quality issues, life-long replacement”, which is the embodiment of our comprehensive service.

Leave A Comment