The company has SA573 Grade 70 carbon steel structural tubing advanced production equipment and machining technology, excellent marketing team and domestic regional channel partners, and sound management plan for product market development and after-sales service. After years of cooperation experience SA573 Grade 70 carbon steel structural tubing, we have accumulated a large number of customers at home and abroad, and won unanimous praise.

Steel materials SA573 Grade 70 carbon steel structural tubing can be classified not only by chemical composition, main quality grade, main performance or use characteristics, but also by habit into carbon steel and alloy steel. Carbon structural steel is easy to smelt, has good processability, low price and large output, and can meet the requirements of common parts of general engineering structure in performance. Carbon structural steel SA573 Grade 70 carbon steel structural tubing is usually rolled into steel plates and various sections, which are used for mechanical parts such as factory buildings and bridges.

Weather-resistant steel plate refers to steel plate that is resistant to weathering and corrosion. SA573 Grade 70 carbon steel structural tubing, Weather-resistant steel plate can adapt well to the environment and is widely used in construction, bridges, roads and other fields with outstanding performance characteristics. One of the outstanding advantages of weather-resistant steel plate is its ability to adapt to a variety of different environments, whether it is in severe cold areas or tropical areas. The weather-resistant steel plate can better maintain its characteristics in various complex environment.

Large-thickness SA573 Grade 70 carbon steel structural tubing, Z35 grade steel plate is a kind of extra-thick steel plate that is applied under specific environmental conditions, such as the key parts such as the turbine seat ring and guide vane of the generator set. It has high requirements for safety, reliability, and long service life. Develop 200mm-300mm thick steel plate of Z35 level, to ensure that the layer tear resistance reaches Z35 level. 300mm thick Z35 grade steel plate can be used not only in the hydropower industry, but also in the manufacture of other large key equipment, and has broad prospects.

Heat treatment specification and microstructure of SA573 Grade 70 carbon steel structural tubing, 12Cr1MoV alloy plate:Heat treatment specification: quenching 970 ℃, air cooling; tempering 750 ℃, air cooling. Microstructure: bainite + ferrite.Mechanical properties of 12Cr1MoV alloy plate:Tensile strength σb (MPa):≥490(50); Yield strength σs (MPa):≥245(25); Elongation δ5 (%):≥22; area shrinkage ψ (%): ≥ 50; Impact energy Akv (J): ≥ 71; Impact toughness value αkv (J/cm2):≥88(9).

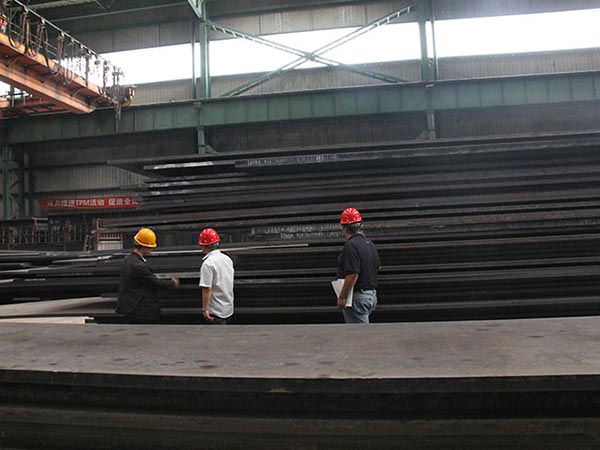

We are known as SA573 Grade 70 carbon steel structural tubing leading manufacturers, suppliers and exporters in the market all over the world. We engage in providing a wide range of plates which are accurately mass produced by using the best quality of parts which gives maximum durability and dependability. The most important thing to know as a potential customer of IRON&STEEL is that we SA573 Grade 70 carbon steel structural tubing stock, processing service, and distribute all of the popular grades of carbon steel plate, alloy steel, shipbuilding steel and boiler steel. Welcome to come China and visit our factory.

We should focus on the main problems to be solved and pay attention to efficiency. After receiving the user's quality objection report data, the possible causes, responsible units, compensation amount, etc. of the problem shall be judged based on experience. To have a clear service plan, to be clear about what your main problem is, what technical support is needed, these should be prepared.

Leave A Comment