The company adopts modern management concept, adheres to “quality for survival, integrity for development”, and provides customers with high-quality and reliable A633 Grade A thickness steel products and wholehearted service. The company conti

The company adopts modern management concept, adheres to “quality for survival, integrity for development”, and provides customers with high-quality and reliable A633 Grade A thickness steel products and wholehearted service. The company conti

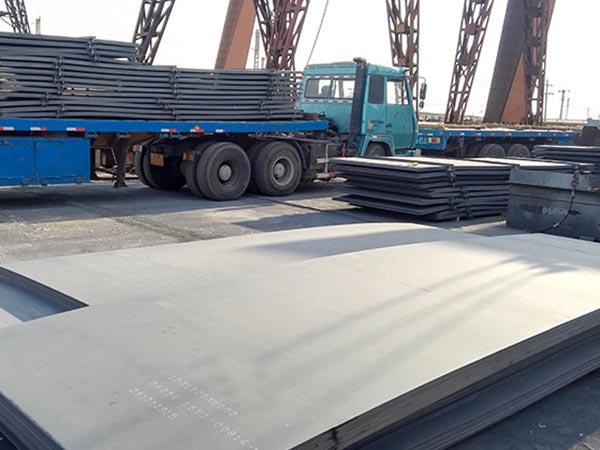

The company adopts modern management concept, adheres to “quality for survival, integrity for development”, and provides customers with high-quality and reliable A633 Grade A thickness steel products and wholehearted service. The company continuously deepens the internal reform of the enterprise, innovates in the reform, develops in the innovation, and gradually forms a set of management and operation mechanism which adapts to the market and has strong competitiveness.

What is the difference between Q235A steel and Q235B steel? First, The carbon content of Q235A steel is 0.22%, higher than that of Q235B steel, which is 0.20%. The sulfur content of Q235A steel is 0.050%, higher than that of Q235B steel, which is 0.045%. Second, A633 Grade A thickness, Q235 material belongs to carbon structural steel. The English letters A and B at the back have different meanings. They are impact temperature requirements. Q235A steel is not subject to impact, while Q235B steel is subject to 20 ℃ room temperature impact.

The elongation of low alloy high strength steel is 15% - 23%, and the impact absorption energy is more than 34J at room temperature. The A633 Grade A thickness, low alloy high strength steel has good plasticity and impact resistance, which can avoid brittle fracture during impact, and make cold bending and welding easy. In addition, the brittle transition temperature of low alloy high strength steel is low, and the absorbed work value of Grade E steel is not less than 27J at - 40℃. This is of great significance to the engineering components and transportation tools such as vehicles, ships, offshore oil platforms, containers, bridges and so on.

Water cutting machine is called water knife for short, that is, water is used as knife. High pressure water jet cutting technology can perform any curve cutting process on any material, A633 Grade A thickness included. The heat generated in the cutting process will be immediately taken away by the water jet without harm. Material, no need or easy to reprocess after cutting, safety and environmental protection, faster, faster, more efficient.

A204 Grade A steel chemical composition(%)Carbon: 0.18-0.25 Manganese max.: 0.90Phosphorus Max.: 0.025Sulfur Max.: 0.025Silicon: 0.15-0.40Molybdenum: 0.45–0.60A633 Grade A thickness, A204 Grade A steel mechanical propertiesTensile strength, kis [MPa]: 265-85 [450-585]Yield strength, min, kis [MPa]: 37 [255]Elongation in 8 in. [200 mm], min, %: 19Elongation in 2 in. [50 mm], min, %: 23

SG255 gas cylinder A633 Grade A thickness steel is widely used in petroleum, chemical industry, power station, boiler, etc, used to make the reactor, heat exchanger, separator. The company is a professional gas cylinder steel exporter and a steel stockist in china. We keep more than 1000 tons SG255 gas cylinder steel coils in A633 Grade A thickness stock every month. If you want to get the steel price, please do not hesitate to contact us. Any need in SG255 Chemical Composition and Mechanical Properties, please feel free to contact us by email or calling to us.

The company formulates clear service process and service standard. To do a good job in after-sales service, first of all, clear service process and service standards should be formulated to let employees know which procedures to perform and which service standards to abide by.

Leave A Comment