In terms of service, our service is a "one-stop" way of working. We have our own a633 grc processing plant and pretreatment plant, pretreatment of ship steel (shot blasting, derusting, painting). Technical parameters of steel plate and profile s

In terms of service, our service is a "one-stop" way of working. We have our own a633 grc processing plant and pretreatment plant, pretreatment of ship steel (shot blasting, derusting, painting). Technical parameters of steel plate and profile s

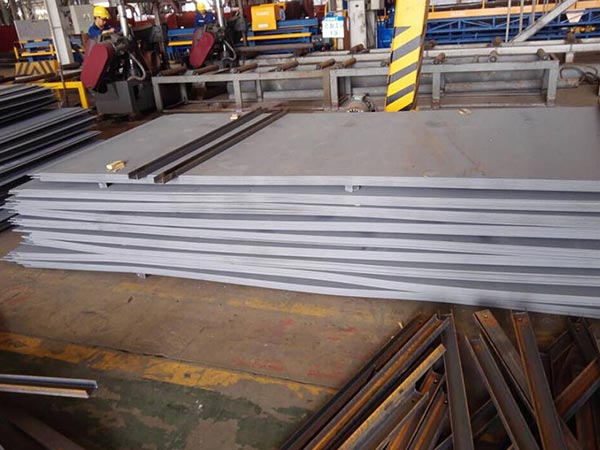

In terms of service, our service is a "one-stop" way of working. We have our own a633 grc processing plant and pretreatment plant, pretreatment of ship steel (shot blasting, derusting, painting). Technical parameters of steel plate and profile steel surface pretreatment production line. We can also let customers enjoy our other pretreatment services, such as a633 grc cutting, welding, drilling, galvanizing, etc., at the lowest cost.

The diameter of large diameter seamless steel pipe is 325mm-1220mm, and the maximum thickness that can be achieved is 200 mm. The diameter of small diameter seamless steel pipe is generally less than 89mm. The processing technology of large diameter seamless steel pipe is hot rolling or hot expanding. There are many materials for large diameter seamless steel pipe, such as a633 grc, which can be processed and customized according to customer requirements. The large diameter seamless steel pipe is usually used in the chemical, petroleum, mechanical and other industries.

We are one of the largest weathering steel stock keepers in China and even in the world. For most specs weathering steel materials, we can arrange delivery within 5 days. Meanwhile, our weathering steel price is competitive. And for weathering steel coils, we do slit, a633 grc plate cut and so on further processing. We can meet different size and shape needs of customers.

Alloying agents like carbon and manganese along with steel lends a malleable nature to A572 structural high tensile steel plates, a633 grc, letting them be formed into various structurals that adapt quickly to constantly evolving needs of an edifice, thereby being flexible to changes. High tensile steel plates facilitate an increased load bearing capacity; their lighter bodies handle the extra weight without giving in to pressures. Heavy lifting and moving vehicles built from them increase weight bearing capacity, reduce time and labour cost to increase profits.

As per JIS G3101 standard, the Carbon (C), Silicon (Si) and Manganese (Mn) content of SS400 steel plate are not controlled. Phosphorus (P) content of a633 grc, JIS SS400 steel plate is 0.050% Max and Sulphur (S) content is 0.050% Max. The SS400 steel melting point is 1430 Degree Celsius, Brinell Hardness is 160HB, density is 7.85g/cm3, Young’s Modulus is 190-210Gpa. The strength and elongation of JIS SS400 steel plate varies with thickness. Generally, the tensile strength of SS400 steel plate is 400-510 Mpa. Elongation is above 21%. Yield strength ≥245Mpa for thickness≤16mm. When the JIS SS400 steel plate is thciker than 100mm, the yield strength shall not less than 205Mpa.

If you want to find wear resistant steel plates or abrasion resistant steel supplier and exporter in China, please visit us. We are one of the leading a633 grc wear resistant steel plates manufactures and stock keepers. We have large stocks for wear resistant steel plates of various grades and dimension. We can not only send offer at the first time, but can also provide technical support and give you professional suggestions and answers about NM400 a633 grc steel specifications, difference between hardox 400 and AR400 and so on question about wear resistant steel plates. Come on! Just call us or send email.

Respect customers and treat each other sincerely. Customers are always right. Always remember that the user is the God of the enterprise, respect the customer, and accept the customer's opinion modestly is the guarantee of the long-term development of the enterprise. Adhere to this concept, so that the service and the product are the same, long-term.

Leave A Comment