Standing at a new historical starting point, we adapt to the requirements of supply side SA573 Grade 58 steel plate composition structural reform, adhere to the overall strategy of "innovation driven, quality leading, quality improving and efficiency increasing, transformation and development", and constantly improve the development concept and development level with a forward-looking vision and grand vision. Now we have been ranked the International leading SA573 Grade 58 steel plate composition steel materials supplier.

In August 2011, the expanded license for the special equipment material manufacturing of SA573 Grade 58 steel plate composition steel plates for heavy steel boilers and pressure vessels successfully passed the expert review and identification. At this point, the company has the qualification to produce steel plates for boilers and pressure vessels with a maximum thickness of 80 mm. Production continues to be at the leading domestic level. Our boiler steel plate has been widely used in the SA573 Grade 58 steel plate composition manufacture of I, II, III pressure vessels and various pressure vessel reaction tanks.

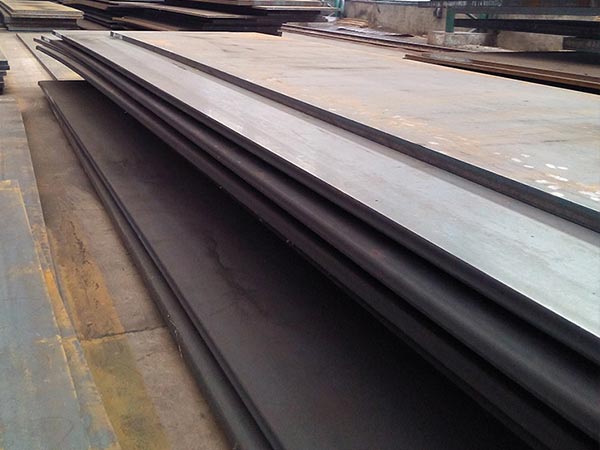

What are the characteristics of medium and thick plate, SA573 Grade 58 steel plate composition? First, the performance of shock resistance and vibration is very good, so the application of medium and thick plates in buildings and bridges can greatly improve the safety. Second, the bearing capacity of medium and thick plate, SA573 Grade 58 steel plate composition is good, the performance is excellent. The bridge, the automobile girder steel plate, and buildings have strict load-bearing requirements, and it is easy to cause accidents if the steel materials not meet the requirements, so the selection of steel is more stringent.

Corrosion resistance mechanism of SA573 Grade 58 steel plate composition, stainless steel: obvious Cr2O3 film is formed on the surface of stainless steel, and the minimum content of O and Cr (10.5%) is required to obtain continuous protective film to prevent corrosion. If the protective film is damaged, it can recover naturally.

A514 gr M alloy structural steel chemical composition (melting analysis)%C: 0.12-0.21, Si: 0.20-0.35, Mn: 0.45-0.70, P max.: 0.035, S max.: 0.035, Ni: 1.20-1.50, Mo: 0.45-0.6.0, B: 0.001-0.005The mechanical properties in thickness (mm)T≤65Yield strength (≥Mpa): 690Tensile strength (Mpa):760-895Elongation in ≥,%: 18

BBN company is an industry leading steel service center that supplies a full line of hot rolled steel plate in a variety of sizes, grades and finishes. Hot rolled steel is an economical option that offers reliable performance and versatility. In the SA573 Grade 58 steel plate composition hot rolled process, high temperature is used to heat the steel above its recrystallization point. In this state it becomes more malleable, allowing it to be easily formed into a variety of shapes. If you are interested in A36 hot rolled plates price, welcome to come and visit us.

Our quality and service commitment: SA573 Grade 58 steel plate composition product quality problems, life-long replacement.In the process of using, any time if you find we supplied steel materials not conform to the requirements of technical standards, we can replace it for you free of charge. However, it should be noted that non product quality problems caused by improper use are not covered by the warranty. Please pay attention to the service time commitment as well as the product quality assurance commitment. Because only the products of big brands and reliable enterprises with complete after-sales service system can truly realize the long-term product quality assurance and the whole process of service.

Leave A Comment