Standing at a new historical starting point, we adapt to the requirements of supply side a573 gr.65 steel structural quality plate structural reform, adhere to the overall strategy of "innovation driven, quality leading, quality improving and efficiency increasing, transformation and development", and constantly improve the development concept and development level with a forward-looking vision and grand vision. Now we have been ranked the International leading a573 gr.65 steel structural quality plate steel materials supplier.

19Mn6 steel is common carbon manganese low alloy steel produced according to DIN17155. 19Mn6 steel has strict control over harmful elements sulfur and phosphorus in chemical composition. The mass fraction of sulfur and phosphorus in the steel a573 gr.65 steel structural quality plate is not more than 0.02%. In addition, vacuum degassing technology is used in smelting, which greatly reduces the gas content in the 19Mn6 steel. 19Mn6 steel has good comprehensive mechanical properties, welding properties and technological properties.

When using a573 gr.65 steel structural quality plate, low-alloy high-strength steel, it is desirable to take advantage of its high strength and use a thinner section, not only for saving weight but also for the economy as much as possible. However, the corrosion factor must be fully considered. The thinner the steel section, the more attention should be paid to corrosion protection. Some low-alloy high-strength steels have good atmospheric corrosion resistance, which can not only improve the effect of anti-corrosion coatings, but in some cases, take appropriate precautions and can even be used without being coated in the atmosphere.

a573 gr.65 steel structural quality plate, The hardened wear-resistant plate is quenched and hardened as a whole, and the martensite in the metallographic structure improves the overall hardness, and the micro hardness and macro hardness are basically the same. Cemented carbide and T10, even if the macroscopic hardness of T12 steel and cemented carbide after quenching is basically the same, the wear resistance of cemented carbide is much higher than that of T12 steel, because there are a large number of carbides in cemented carbide .

As for the mechanical properties of a573 gr.65 steel structural quality plate, ASTM A572 Gr.50, 345 Mpa is the yield point levels most closely approximating a geometric progression pattern between 36 ksi min yield point steels covered by Specification A36/A36M and 100ksi min yield point steels covered by Specification A514/A514M.

The alloy steel plate is among our business scope, and it is one of our main product. If you have any demands or questions about alloy steel plate, such as 34CrMo4 a573 gr.65 steel structural quality plate material properties, 42CrMo4 AISI equivalent, 12Cr1MoV equivalent ASTM, 40Cr material specification, 42CrMo hardness, 50CrMo4 chemical composition and so on, please free free to communicate with us. We have professional technical team and sales team, who will give you a573 gr.65 steel structural quality plate professional answers and quotation about alloy steel plate in time.

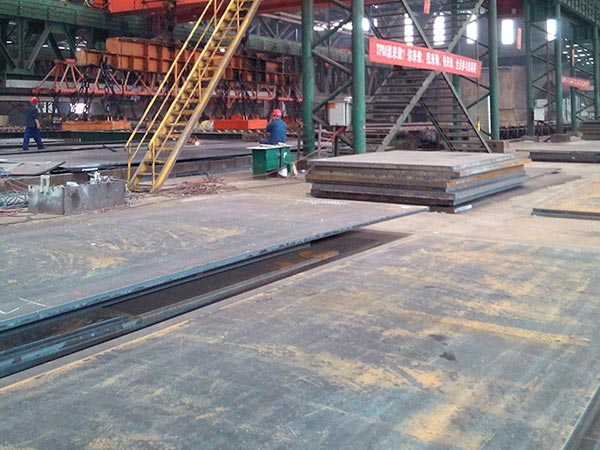

Before delivering our hot rolled plate product we apply various tests to check the quality of carbon steel a573 gr.65 steel structural quality plate plates such as- mechanical test, chemical test, hardness test, toughness test, eddy current test, impact test, micro test, flaring test, flattening test, etc. We are provided best packing for structural steel plates to avoid rust. Our after-sales service team will contact you if you have any question.

Leave A Comment