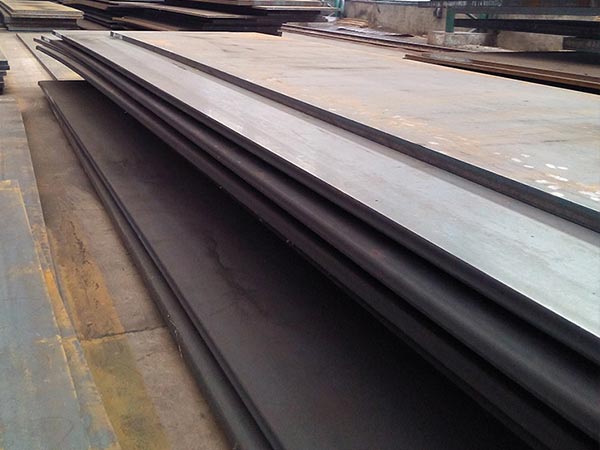

Low alloy steel plate was originally developed for large diameter oil and gas pipeline in 1960s. Pipeline steel materials used in oil and gas projects require higher strength and toughness than low carbon steel, and have good weldability just the same as low carbon steel.Advantages: A573 Grade 65 carbon plate, Low alloy steel plate has superior performance and light weight.Disadvantages: Low alloy steel plate is killed steel, so the price will be more expensive.

The company adheres to the "variety, quality and efficiency" road. We have established a technology center, a brand cultivation management system and a quality control system. Now the company has formed an independent innovation system integrating A573 Grade 65 carbon plate production, learning, research and marketing. Our company has passed ISO9001 quality management system certification and ISO10012 measurement management system certification.

Semi-endless rolling technology has three advantages: the A573 Grade 65 carbon plate product's limit thickness and limit width specification range has been significantly expanded. The thinnest thickness of SPHC steel has been expanded from 1.0 mm to 0.78 mm, and the limit specification product width has been expanded from 1100 mm to 1300 mm; The thinnest thickness of Q235B steel has been expanded from 1.2 mm to 1.0 mm, and the width range of the limit specification products has also been further expanded.

"The production method of seamless steel pipe can be roughly divided into cross rolling method (menesmann method) and extrusion method. The cross rolling method (menesmann method) is to pierce the tube blank with the cross roll first, and then extend it with the rolling mill. This method is fast in production, but requires high machinability of tube blank. It is mainly suitable for producing carbon steel and low alloy steel tube, A573 Grade 65 carbon plate tube.The extrusion method is to pierce the billet or ingot with a piercer, and then extrude it into a steel tube with an extruder. This method is less efficient than the cross rolling method and is suitable for the production of high-strength alloy steel tubes."

The after-sales service department will pay return visit to each customer by call or email, report problems found during the return visit in time, and discuss with the production and quality inspection center to propose effective solutions and follow up in a timely manner, so as to ensure the benefits each customer are fully guaranteed, and to provide customers with more value-added services.

Leave A Comment