The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our A633 Gr E factory steel products are supplied in time, with reliable quality and perfect and thoughtful after-sales

The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our A633 Gr E factory steel products are supplied in time, with reliable quality and perfect and thoughtful after-sales

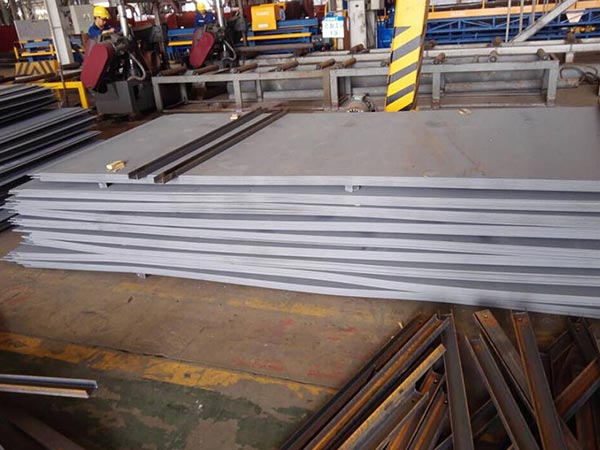

The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our A633 Gr E factory steel products are supplied in time, with reliable quality and perfect and thoughtful after-sales service. Meanwhile, we have huge A633 Gr E factory steel stocks all the year round. The company long-term pursues the principle of quality first, customer first, quality for survival, reputation for development, and perfect service to win the users.

As a leading international steel supplier, we have two warehouses, close to Tianjin port and Shanghai port. This superior geographical location effectively saves the domestic transportation cost and greatly improves our service level. At the same time, it also shortens our delivery time and provides more convenience for customers.

Rolling steel is the process of pressing to change the shape of the ingot and billet between the rotating rolls. The so-called steel rolling process is a combination of a series of steel rolling processes. The entire rolling production process is always composed of the following A633 Gr E factory basic processes: ① billet preparation:Including the cleaning of surface defects, the removal of surface scale and the pre-heat treatment of billets. ② billet heating ③ steel rolling: it is the core of the entire rolling production process. ④ Finishing.

In December of 2015, our regular India customer sent us an inquiry for A633 Gr E factory pipe. The inquiry requires no negative tolerance in both pipes’ outer diameter and pipe wall. After two weeks’ discussion, he put the order of 275 tons to us. The pipes are finished within just one month. Our customer come to our factory to inspect the quality and tolerance, all the products are well meet his demand. The pipes are arriving to Nhava Sheva port, customer is very happy with our products and service during the process.

40Cr grade under GB/T 3077-2015 standard is a alloy steel bar material. A633 Gr E factory, 40Cr alloy chemical composition (C: 0.37 ~ 0.44, Si: 0.17 ~ 0.37, Mn: 0.50 ~ 0.80, Cr: 0.80 ~ 1.10, Ni: ≤0.30, P: ≤0.030, S: ≤0.030, Cu: ≤0.30, Mo: ≤0.10). Heat treatment: First quenching heating temperature (℃): 850; coolant: oil; Temperature heating temperature (℃): 520. 40Cr steel tensile strength (σb / MPa): ≥980. Yield point (σs / MPa): ≥785

The company uses online training system to let all employees use fragmented time to carry out targeted training anytime, anywhere, regardless of time and geographical restrictions. Through training to improve A633 Gr E factory work skills, at the same time, through training, let all improve their own quality education level, let employees work around a goal, create a career and achieve results.

Leave A Comment