Analyze the advantages and disadvantages of the products against the competitive products. Understand the industry situation and future trend. Understand the high strength structural steel grades product brand positioning appeal point, focus on the crowd and development direction. Understand the layout of each market area, and form a big strategic layout view. Understand the basic operation and assessment standards of work responsibilities. Understand the situation of the cooperative customers.

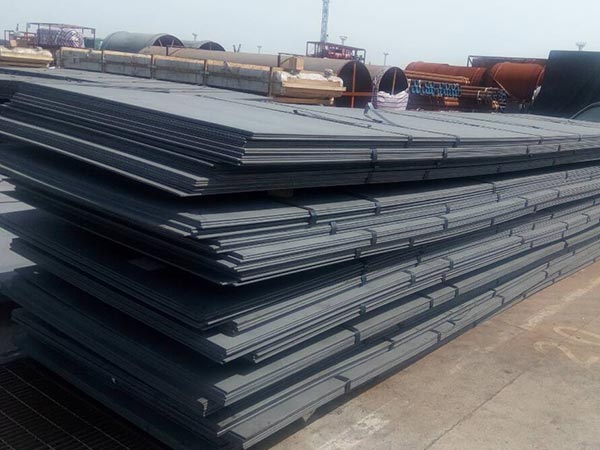

The qualified flat steel has sufficiently high high temperature strength and high temperature plasticity. Therefore, high strength structural steel grades flat steel is not only required to have high enough normal temperature and instantaneous high temperature tensile strength and plasticity, but also long-term strength and long-term plasticity to ensure long-term safe work at high temperatures, especially under creep leakage conditions. The product thickness is 8-50mm, width 150-625mm, length 5-15m。

Weathering steel generally adopts the process route of fine material into the furnace-smelting (converter, electric furnace-microalloying treatment-argon blowing-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and cooling. The scrap steel is added into the furnace together with the charge, and smelted according to the conventional process. After the high strength structural steel grades steel is tapped, deoxidizers and alloys are added. After the molten steel is treated with argon blowing, the molten steel is cast. By adding rare earth elements to the steel, the high strength structural steel grades weathering steel is purified and the content of inclusions is greatly reduced.

Hardness comparison between Q345B steel and NM450 steel: wear resistant steel for construction machinery requires high wear resistance, high toughness, impact resistance, easy welding, easy forming and other high-performance characteristics. The main index of wear resistance is the surface hardness. The higher the hardness, the better the wear resistance. Compared with high strength structural steel grades, Q345B steel, the hardness of NM450 steel is only increased 3 times, but the average service life is increased 6-8 times under the same working conditions.

Our ogistics department has a professioanl team to support the goods’ transportation and delivery time. Its responsibilities: make customs clearance documents, track products production process, and update shipping information for customers. The company will adhere to the mission of reflecting social values, take the scientific management system as the guarantee of daily operations, and provide continuous technological innovation to support its sustainable development.

our company is leading supplier of API 5CT casing pipes in China. N80 oil casing pipes enjoy high size precision, good weld toughness, high strength structural steel grades good extrusion resistance, easy quality control and low cost features. Welcome to our company to purchase high strength structural steel grades API 5CT N80 and so on casing pipes.

Leave A Comment