After comprehensive and professional training such as customer service, the customer service team has more strict discipline in the management of customer service team to ensure that customer service personnel respond to customers with a professional attitude. A process supervision system has been set up to let each customer supervise the process of the system with us

ASTM a588 steel beam SA299 Gr.A carbon steel plate not only has high tensile and yield strength, but also has good atmospheric corrosion resistance due to its small copper content. Due to its high strength, its SA299 Gr.A carbon steel plate weight is less than that of A36 steel section without reducing strength. At the same time, it is the best material for outdoor application, the surface is orange.

Plasma cutting has a wide range of applications. With different working gas, it can cut various kinds of metals that are difficulty to handle by oxygen cutting. Plasma cutting is fast and efficient when cutting metal with small thickness. The SA299 Gr.A carbon steel plate cutting speed can reach more than 10m/min. Plasma cutting can get a clean, neat, non stick slag cutting surface, while the deformation and thermal effect of the incision are small, its hardness change is little, and the cutting quality is good.

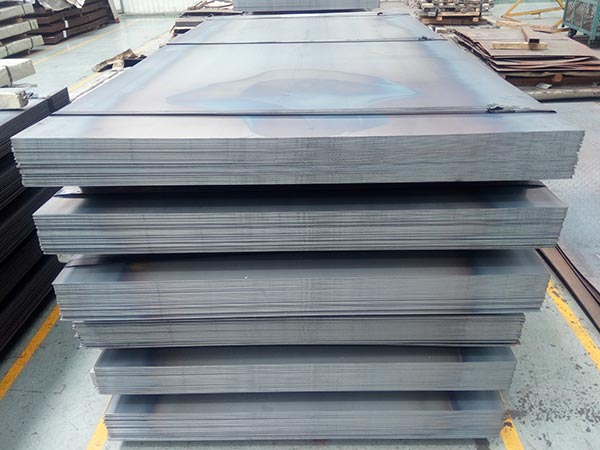

"We can supply carbon steel plate, SA299 Gr.A carbon steel plate, hot rolled plate and structural steel sheet with high quality and various size. Thickness from 5mm to 300mmWidth: from 1,500mm to 2,500mmLength: from 6,000mm to 12,000mmTechnical conditions: Ultrasonic tested as per SA 578 or any other as per requirementMTC acc to EN 10204 / 3.2"

Box making, door-to-door: fill in the packing plan: box making time, ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, door point, contact person, telephone number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date). Internal loading: fill in the packing plan: ship name, voyage number, customs declaration number, transfer port, destination port, gross weight, number of pieces, volume, cabin number, etc., and arrange the train shift 1-2 days before the closing date (two days before the ship's date).

The company specializes in hot rolled plates producing, steel plate processing, steel plates cutting, carbon steel plate weldding and exporting of wide and thick steel plates. BBN company has high-quality CNC SA299 Gr.A carbon steel plate steel plate cutting processing equipment, professional technical personnel, and supporting marketing and after-sales service system. Sincerely welcome new and old customers to visit our company, BBBN company will always be your reliable choice.

Leave A Comment