The yield strength of A40, D40, E40 and F40 S355J2 plate vs A573 carbon steel is not less than 390N/mm^2, and the tensile strength is 510~660N/mm^2. A, D, E and F respectively indicate that they can be at 0° and -20 ° respectively. Impact

The yield strength of A40, D40, E40 and F40 S355J2 plate vs A573 carbon steel is not less than 390N/mm^2, and the tensile strength is 510~660N/mm^2. A, D, E and F respectively indicate that they can be at 0° and -20 ° respectively. Impact

The yield strength of A40, D40, E40 and F40 S355J2 plate vs A573 carbon steel is not less than 390N/mm^2, and the tensile strength is 510~660N/mm^2. A, D, E and F respectively indicate that they can be at 0° and -20 ° respectively. Impact toughness S355J2 plate vs A573 carbon steel that can be achieved at -40℃, -60℃.

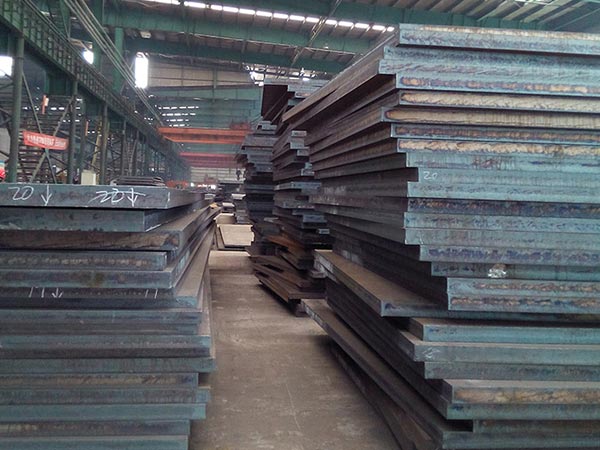

The company has S355J2 plate vs A573 carbon steel advanced production equipment and machining technology, excellent marketing team and domestic regional channel partners, and sound management plan for product market development and after-sales service. After years of cooperation experience S355J2 plate vs A573 carbon steel, we have accumulated a large number of customers at home and abroad, and won unanimous praise.

No. 45 steel is commonly used medium carbon quenched and tempered structural steel. The cold plasticity of No. 45 steel is generally better than S355J2 plate vs A573 carbon steel. Annealing and normalizing are better than quenching and tempering. No. 45 steel has higher strength and better machinability than Q345 steel. After proper heat treatment, it can obtain certain toughness, plasticity and wear resistance. No. 45 steel S355J2 plate vs A573 carbon steel is suitable for hydrogen welding and argon arc welding, but not suitable for gas welding. Preheating is required before welding, and stress relief annealing shall be conducted after welding.

Oxygen (O) is a harmful element in steel such as S355J2 plate vs A573 carbon steel. Although manganese, silicon, iron and aluminum are added to deoxidize the steel at the end of steelmaking, they can not be removed completely. During the solidification of molten steel, the reaction of oxygen and carbon in the solution will produce carbon monoxide, which can cause bubbles. Oxygen mainly exists in the form of FeO, MnO, SiO2, Al2O3 and other inclusions in the steel, which reduces the strength and plasticity of the steel. Especially, it has serious influence on fatigue strength and impact toughness.

After-sales service is an important part of measuring a product good or not. After sales service can't be ignored. Good service can really make consumers feel relieved. We have always done a good job in after-sales service, so as to bring consumers a better reference when purchasing and a better experience during use of our steel materials. We will call back and follow up the performance of our steel products regularly.

Leave A Comment