At the same time of doing well in carbon steel structural tubing production and operation, Yunnan company focused on completing the four phases of technical transformation construction projects, realizing industrial upgrading, improving equipment level, and laying a good foundation for the future development of the company. In the carbon steel structural tubing technological transformation project, pollution control facilities have been built synchronously, and a large number of comprehensive utilization projects, such as comprehensive sewage treatment and recycling project, blast furnace gas waste heat and residual pressure power generation, have been invested and constructed.

Using advanced logistics management, advanced models and management experience to increase the reliability of logistics operations and provide customers with 24/7 cargo management. On the premise of reducing transportation and management costs as much as possible, we provide customers with high-quality and efficient services; good business reputation has been recognized and supported by our customers.

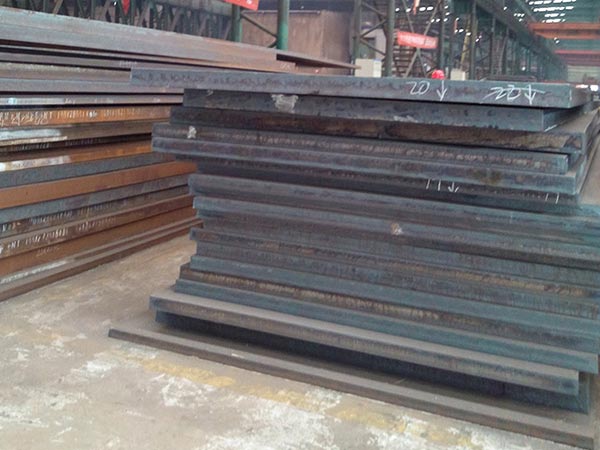

The related factors of carbon steel structural tubing steel plate cutting are mainly steel plate material, steel plate specific use and steel plate cutting requirements, so it can be said that there are many related factors. Different processing methods, such as finish machining and rough machining, choose different carbon steel structural tubing steel plate cutting methods. Wire cutting or plasma cutting is used for finishing and flame cutting is used for rough machining. Therefore, it can be concluded that the steel plate cutting methods selected under different processing methods are different.

In Nov, 2018, our Mozambique customer purchased from BBN company 500 tons carbon steel Q235B steel structure for building 10 units of gas station. We have been cooperate more than 5 years for providing plate and pipes and carbon steel structural tubing profile as beginning, and they are very satisfied with all the received Cargo. We extend in-house cutting, welding, grinding, bending and certification and testing of our products, on client demand. If you are interested in our steel structures or steel plate price, welcome to contact us.

The difference between carbon steel structural tubing, 10# seamless steel pipe and 20# seamless steel pipe: 1. Chemical composition Chemical composition of 10# seamless steel pipe: C: 0.07-0.13, Si: 0.17-0.37, Mn: 0.35-0.65, Cr: 0.15, Ni: 0.30, Cu: 0.25. Chemical composition of 20# seamless steel pipe: C: 0.07-0.23, Si: 0.17-0.37, Mn: 0.35-0.65, Cr: 0.25, Ni: 0.30, Cu: 0.25 2. Mechanical properties 10# seamless steel pipe: tensile strength: 335 MPa, yield strength: 205 MPa, elongation: 31%. 20# seamless steel pipe: tensile strength: 410 MPa, yield strength: 245 MPa, elongation: 25%.

Advanced typical figures and typical deeds are the embodiment and symbol of carbon steel structural tubing enterprise spirit, outstanding ideas and vivid images, with strong demonstration, radiation and transmission effect. Without distinctive typical characters, there is no unique enterprise culture. In carrying out the construction of enterprise culture, the advanced enterprise culture should be typified. Vigorously excavate, discover, cultivate and summarize the company's carbon steel structural tubing advanced models.

Leave A Comment