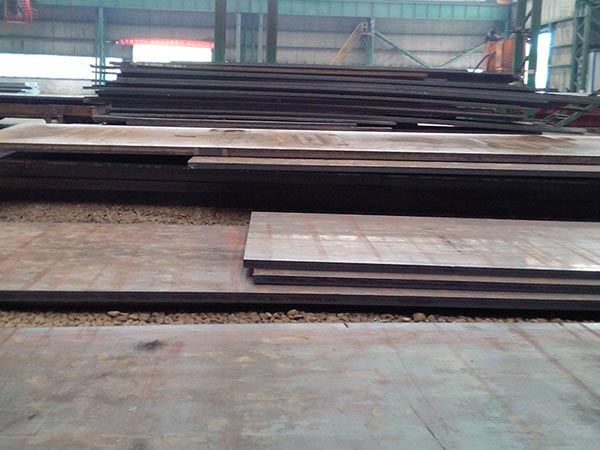

The steel plate cutting and processing instructions are as follows: steel plate cutting and steel plate cutting processing, as well as SA573 Grade 65 carbon plate packaging steel plate zero cutting processing. There are semi-automatic flame cutting, fully automatic CNC cutting, laser cutting and water cutting. The thickness range of steel plate that can be cut is 20650mm. In terms of SA573 Grade 65 carbon plate packaging steel plate cutting types, there are Q235B common plate, Q345B low alloy plate and 45 carbon bonded plate.

The weldability of SA573 Grade 65 carbon plate packaging is good. It means that under certain process and construction conditions, SA573 Grade 65 carbon plate packaging can obtain good performance after welding. Weldability is a measure of the hot workability of steel. Weldability can be divided into weldability in construction and weldability in use. Weldability in construction refers to the sensitivity of cracking in weld metal and near seam zone, and hardening sensitivity of steel in near seam zone. Good weldability means that under certain welding process conditions, the weld metal and steel near the seam do not produce cracks. Weldability in use means that the mechanical properties of weld and HAZ steel are not lower than those of base metal.

Hot rolled plates are known for their superior mechanical properties over commodity grades of merchant bar. The hot rolled SA573 Grade 65 carbon plate packaging plates products are made to specific chemistry and mechanical properties ranges, allowing them to be used in engineered applications. Resulting shafts, axles, and gears can be used in the automotive SA573 Grade 65 carbon plate packaging industry and agriculture equipment. A36 mild steel has good strength, formability, and excellent welding properties. We also can supply welding, fabricating, and bending service.

Safety production is the cornerstone of enterprise survival and development. The company established a safety management network, which achieved clear powers and responsibilities, clear responsibilities, effective management and control, and provided organizational guarantee for safe production. The company strictly complies with the "Environmental Protection Law", establishes an effective environmental protection emission control system and waste gas, waste water, waste solid recycling system, and makes great efforts to harden, lighten, green, and beautify the plant, and strive to build green steel enterprises.

Leave A Comment