45# seamless steel pipe (No.45 seamless steel pipe) is Chinese high-quality carbon structural steel, which is called S45C in Japanese standard, AISI 1045 in American standard, and C45 in German standard. The difference between 45# seamless steel pipe and 20# seamless steel pipe is that its hardness is obviously higher than that of 20# seamless steel pipe. The tempering brittleness of SA573 Grade 65 material, 45# seamless steel pipe is high. After quenching and tempering, 45# seamless steel pipe has good mechanical properties. If the wear resistance is considered, heat treatment is required.

The company's operation is based on the principle of "quality for survival, reputation for development". In terms of management, we adhere to the principle of people-oriented, service-oriented and customer-oriented. All staff of the company have the courage to open up, unite and forge ahead, and work hard to grasp the good situation of global economic development, actively strengthen communication with outstanding enterprises in the SA573 Grade 65 material industry, keep pace with the times, and move towards a new course!

The correct choice of billet type, section shape, size and weight are of great significance to SA573 Grade 65 material steel rolling production. Steel rolling production has certain technical requirements for raw materials, such as steel type, section shape, size, weight, and surface quality. The consideration of these technical requirements is necessary to ensure the quality of steel. It should also be specifically considered when determining and selecting the blank. The SA573 Grade 65 material rolling method can be divided into cold rolling and hot rolling according to the rolling temperature.

In order to obtain the seamless tube with smaller size and better quality, the method of cold rolling, cold drawing or the combination of the two must be used. Cold rolling is usually carried out on a two high mill, and SA573 Grade 65 material pipes are rolled in a circular pass composed of a variable cross-section circular groove and a fixed conical head. Cold drawing is usually carried out on single chain or double chain cold drawing machines of 0.5-100t.

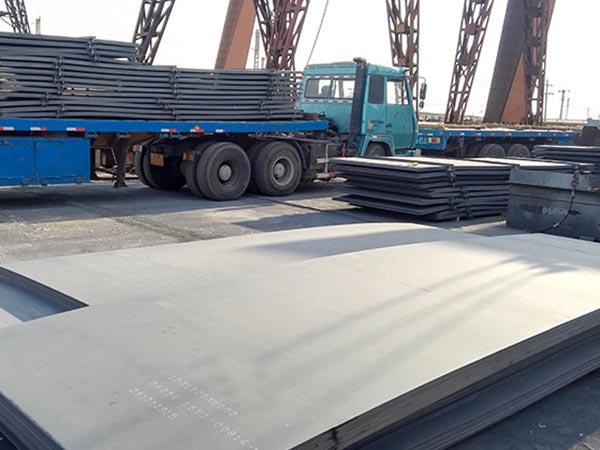

Before delivering our hot rolled plate product we apply various tests to check the quality of carbon steel SA573 Grade 65 material plates such as- mechanical test, chemical test, hardness test, toughness test, eddy current test, impact test, micro test, flaring test, flattening test, etc. We are provided best packing for structural steel plates to avoid rust. Our after-sales service team will contact you if you have any question.

Leave A Comment