The company specializes in the research and development, production and sales of A633 Grade A impact test seamless pipes, longitudinally welded pipes, large-diameter welded pipes, API 5L welded pipes, spiral welded pipes, and large-diameter thick-walled straight seam steel pipes. The company has A633 Grade A impact test five production lines in three major production workshops: large-diameter longitudinally welded pipe production workshop,A633 Grade A impact test rolled steel pipe production workshop, and thermally expanded steel pipe production workshop, with an annual production capacity of more than 100,000 tons.

15CrMo alloy plate is a heat-resistant steel with pearlite structure, which has high thermal strength (δb≥440MPa) and oxidation resistance at high temperatures, and has a certain resistance to hydrogen corrosion. Due to the high content of Cr, C and other alloying elements in steel, the hardening tendency of A633 Grade A impact test and 15CrMo alloy plate is obvious and the weldability is poor. After welding, local high temperature tempering treatment should be carried out. The heat treatment process of 15CrMo alloy plate is as follows: the temperature rise rate is 200°C/h, the temperature is raised to 715°C for 1 hour and 15 minutes, the temperature drop rate is 100°C/h, and the temperature is reduced to 300°C before air cooling.

DC53 mold steel has better machinability and abrasiveness than SKD11. DC53 cold work die steel A633 Grade A impact test is widely used in punching die, cold work forming die, cold drawing die; forming roll, punch; precision stamping die; precision cutting die for wire cutting and punching die for various purposes; difficult to process materials Tools for plastic deformation; cold forging, deep drawing and thread rolling dies; high-speed punching punches, stainless steel punches.

Laser cutting, it is a specific way of cutting A633 Grade A impact test steel plate cutting processing, is also one of the common way of cutting its on the cutting or machining parameters, if you want to get the right number, is that you can adjust these parameters to achieve a goal, adjust a few times more to get accurate numerical right in addition, we also need to know is, the faster the cutting A633 Grade A impact test speed, the light intensity is smaller, so, the smaller the laser penetration is, in turn, can control the penetration depth of laser.

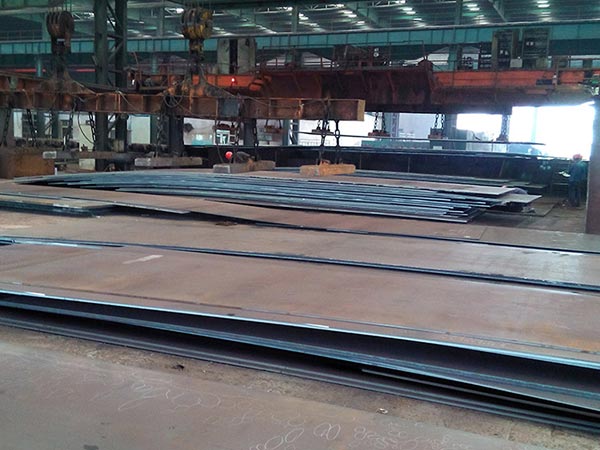

BBNSteel boiler plate A633 Grade A impact test for sale: 14*1510*4000, 14*2520*6000, 15.5*2900*12050, 15*2120*5620, 15*1780*6000, 14.5*2670*5600, 14*1530*6700, 15.5*2900*8400, 15.5*2030*10300, 15*3000*7800, 15.5*1820*6000, 14*3050*4000, 16*3000*10000, 16*1300*6000, 15*3000*7830, 15.5*2500*7100, 15*1740*8870, 17*3000*4900, 16*2540*5100, 15.5*2560*6900, 16.5*2720*4500.

Since its establishment, the company has been deeply supported and loved by customers with its unique business philosophy and business model. The company has always adhered to the tenet of "credibility first, integrity-based, quality first" and sincerely serves new and old customers. At the same time, it keeps pace with the times based on market orientation, continuously expands offline channels, and gradually establishes a complete online E-commerce business management platform. We will always promote our after-sales service to make client satisfied with our goods.

Leave A Comment