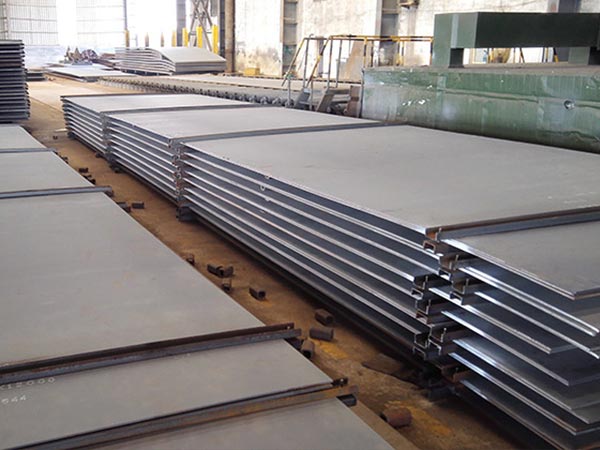

High strength wear-resistant plate is a kind of plate product used for large area wear condition. It is made by overlaying a certain thickness of high hardness and excellent wear-resistant layer on the surface of ordinary low carbon steel or low alloy steel with good toughness and plasticity. After production, the high-strength wear-resistant plate will be tested for its strength and bearing pressure. High strength wear-resistant plate is very wear-resistant, in the case of no accident, the service life of 10mm thick SA573 Grade 65, high-strength wear-resistant plate is very long.

10mm thick SA573 Grade 65, 20CrMo alloy steel plate has high hardenability, no temper brittleness, good weldability, little tendency of cold cracking, good machinability and cold strain plasticity. 20CrMo alloy steel plate is generally used in the state of quenching and tempering or carburizing and quenching. 20CrMo alloy steel plate is used to manufacture high-pressure pipes, fasteners and carburized parts, such as gears and shafts, working in non corrosive medium and medium containing mixture of nitrogen and hydrogen under 250 ℃.

Laser cutting 10mm thick SA573 Grade 65 has no burr, wrinkle and precision is high. It is superior to plasma cutting. Laser cutting has good cutting quality, narrow cutting width (generally 0.1-0.5m m), high accuracy (generally 0.1-0.4mm hole center distance error, 0.1-0.5mm contour dimension error), good surface roughness (generally Ra is 12.5-25μm), and the 10mm thick SA573 Grade 65 cutting seam can be welded without further processing. Fast cutting speed: for example, with 2kW laser power, the cutting speed of 8mm thick carbon steel is 1.6m/min.

The company specializes in hot rolled plates producing, steel plate processing, steel plates cutting, carbon steel plate weldding and exporting of wide and thick steel plates. BBN company has high-quality CNC 10mm thick SA573 Grade 65 steel plate cutting processing equipment, professional technical personnel, and supporting marketing and after-sales service system. Sincerely welcome new and old customers to visit our company, BBBN company will always be your reliable choice.

We have a professional after-sales service team, the company has developed a clear service process and service standards, after-sales service team members strictly perform after-sales procedures, comply with service standards. The most important thing is that we have set up the correct concept of after-sales service, "customer first, sincere service for users".

Leave A Comment