Our company has sales department, technology department, quality inspection department, after-sales department, logistics department. Each department has professional knowledge and high professional quality, put customers first, think about the interests of customers, actively communicate with customers and solve problems smoothly.

NM400 wear resistant steel plate has a very high mechanical strength; its mechanical properties are 3 to 5 times that of ordinary low alloy steel plates; it can improve the wear resistance of mechanical related parts; therefore improve the service life of machinery; reduce production costs. The surface hardness of the product 10mm thick SA573 Grade 65 plate is usually Reached 360 - 450HB. NM400 wear resistant steel plate is used for processing and manufacturing of wear-resistant and wearing parts for mining and various construction machinery.

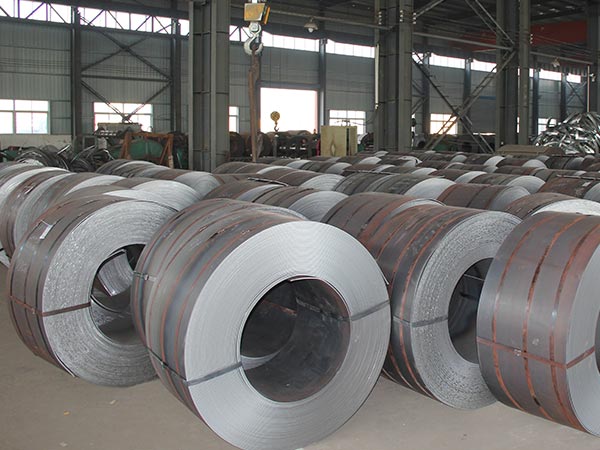

Medium and high carbon alloy hot rolled plates are mainly used in cold rolling and calendering, saw blades and tool industries. The company has taken advantage of smelting, hot rolled 10mm thick SA573 Grade 65 plate plate and coil finishing equipment and technical advantages, and has successfully developed a batch of high-carbon and its alloy steel and medium-carbon high-alloy 10mm thick SA573 Grade 65 plate steel hot-rolled coils with the goal of replacing imports. The iron oxide scale is delivered and trusted by high-end users.

The Egypt customer ordered 130 tons 10mm thick SA573 Grade 65 plate stainless steel plate in stock, and this batch has left port today for its destination today(October 25th, 2019). 316l stainless steel is molybdenum-bearing austenitic stainless steel. This material has better corrosion resistant property than 304/314L for it's higher Ni and Mo content. (it is considered to be marine grade stainless steel, not suitable for warm sea water treatment). 316L austenitic stainless steel supplied by our company has good formability and weldablity, additionally it is proved to have excellent properties of tensile, creep and stress-rupture strengths in elevated temperature environment.

Leave A Comment