Our hot rolled mild steel sheets offer excellent corrosion resistance property in the server’s environments. The mild steel sheets provide high resistance to nitric and chloride corrosion in sulfide solutions. These SA283 GrC carbon steel plates astm a656 grade 80 welding offer high strength, tensile, yield, mechanical strength, ductility, hardness, toughness, etc. Mild steel sheet is worked very easily in a high-temperature application and show excellent resistance to chloride crossing and cracking stress.

We can process the steel materials according to your drawing. Or if you can not make drawing, please send us astm a656 grade 80 welding specific data and requirements, our technical department can make design and drawing for you, and then confirm with your technician or engineer. If all is OK, our processing center will process the steel materials according to the drawing. So no matter what size and shapes you need, we can meet demands at the most time.

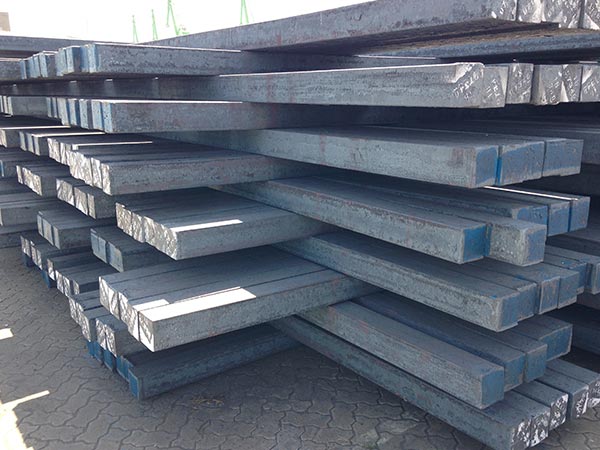

In 2014, we offered 175 ton Cold rolled stainless steel plate to Thailand. The astm a656 grade 80 welding products are from TISCO. Here is the MTC that we offered to customer. We have our own quality team. Our quality team will inspect every order before shipment for customer. Normally, we will test the chemical composition, thickness, width, and length. Here are some pictures for last inspection.

Non-destructive flaw detection of steel plates is a test method for inspecting the astm a656 grade 80 welding surface and internal quality of the inspected parts without damaging the working state of the workpiece or raw materials. Commonly used astm a656 grade 80 welding steel plate flaw detection methods include: X-ray flaw detection, ultrasonic flaw detection, magnetic particle flaw detection, penetration flaw detection, eddy current flaw detection, gamma-ray flaw detection, fluorescent flaw detection, color flaw detection and other methods. Physical flaw detection is non-destructive flaw detection without any chemical changes.

The wear-resistant layer of astm a656 grade 80 welding wear-resistant steel plate is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are added. The carbide in the microstructure is distributed in the form of fiber, and the direction of the fiber is perpendicular to the surface. The microhardness of carbides can reach hv1700-2000 and HRC58-62 respectively. The alloy astm a656 grade 80 welding carbide has strong stability at high temperature, high hardness and good oxidation resistance. It can be used normally within 500 ℃.

Our company was founded in 2009, and has been committed to steel business since its establishment. Over the years, the company's performance shows a good development trend, with a wide range of customers in the government, domestic and foreign markets. The company has always been in line with the tenet of "based on trust and win with quality", focusing on the market demand, with a long-term vision, with years of hard work and trustworthy operation, and the support of the majority of astm a656 grade 80 welding businesses and customers, has won the unanimous praise and trust of the industry and customers!

Leave A Comment