Our company has sales department, technology department, quality inspection department, after-sales department, logistics department. Each department has professional knowledge and high professional quality, put customers first, think about the interests of customers, actively communicate with customers and solve problems smoothly.

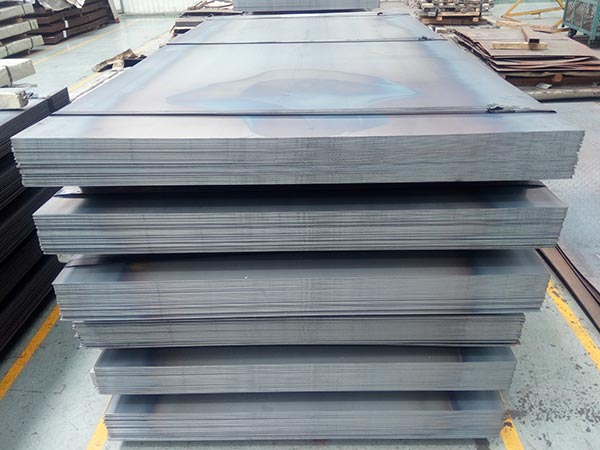

For a ship, the choice of medium and thick ship plate is very important, it is an important part of the ship frame. The pressure bearing capacity of A573 Grade 58 welded construction, medium and thick ship plates is very strong. Secondly, because it is a ship plate, it must be driven in water, so of course the corrosion resistance is better, otherwise it will bring danger to buyers. Moreover, the service life of the ship will be increased. Regular inspection of the ship plate can ensure the safety of sailing. You can also know whether the ship plate is defective, so you don't have to worry about water seepage when you sail.

Non-destructive flaw detection of steel plates is a test method for inspecting the A573 Grade 58 welded construction surface and internal quality of the inspected parts without damaging the working state of the workpiece or raw materials. Commonly used A573 Grade 58 welded construction steel plate flaw detection methods include: X-ray flaw detection, ultrasonic flaw detection, magnetic particle flaw detection, penetration flaw detection, eddy current flaw detection, gamma-ray flaw detection, fluorescent flaw detection, color flaw detection and other methods. Physical flaw detection is non-destructive flaw detection without any chemical changes.

We supply 5800 tons A53 Gr B ERW pipes to Qatar for Qatar Integrated Railway Project - Green Line. This is the first Metro Line in Qatar, and it is located in Doha. We got the order by tender, launched by the Qatar Railways Company for designing, construction and completion of Green Line Project. Before putting order, a delegation from the A573 Grade 58 welded construction project side visited us and several other famous steel pipe mills in China for 15 days. Finally, we were chosen and finished the task exceeding their expectations.

Leave A Comment