It is very important for an enterprise to have a sound after-sales service system, which not only ensures the normal outflow and inflow of the company's products, but also improves the trust of the company's products in the hearts of customers.

It is very important for an enterprise to have a sound after-sales service system, which not only ensures the normal outflow and inflow of the company's products, but also improves the trust of the company's products in the hearts of customers.

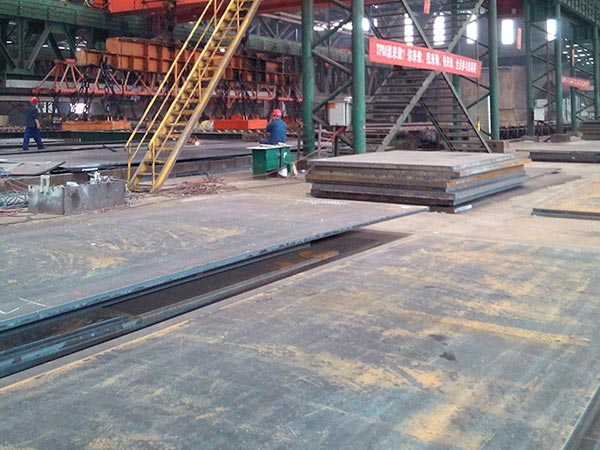

It is very important for an enterprise to have a sound after-sales service system, which not only ensures the normal outflow and inflow of the company's products, but also improves the trust of the company's products in the hearts of customers. Our company has a special after-sales service team and good after-sales service reputation. In case of any problem in the use of our steel products carbon structural steel supplier , whether quality problem or not, the after-sales service department will assist in solving the problem as soon as possible, and regularly consult and track the use of the steel products.

The elongation of low alloy high strength steel is 15% - 23%, and the impact absorption energy is more than 34J at room temperature. The carbon structural steel supplier, low alloy high strength steel has good plasticity and impact resistance, which can avoid brittle fracture during impact, and make cold bending and welding easy. In addition, the brittle transition temperature of low alloy high strength steel is low, and the absorbed work value of Grade E steel is not less than 27J at - 40℃. This is of great significance to the engineering components and transportation tools such as vehicles, ships, offshore oil platforms, containers, bridges and so on.

Since the welding process is often used in the fabrication and processing of steel structures, it is very important for low-alloy high-strength steels of such purpose to be welded using the arc welding process that is widely used in thin thickness plates and steel strips. Yes, the welding seam of the steel structure should have the required strength and toughness, so as to withstand the most unfavorable conditions for the intended use. At present, the development of carbon structural steel supplier, low-alloy high-strength steels is carried out simultaneously with the development of various welding processes. Most low-alloy high-strength steels can be welded well.

In year 2015, we supplied 950 tons S355J0 angle steel to Egypt government. We have cooperation with local government for more than 3 years. Every year, they would order more than 3000 tons of carbon structural steel supplier steel from our company.

Leave A Comment