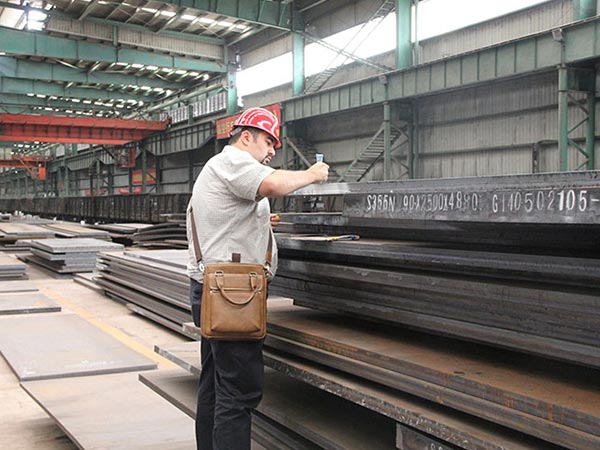

Every customer who has visit us and witness the steel materials before delievry will be impressed by our quality control departemnt. Even not come to inspect the steel materials before delievry, our quality control departemnt will also send inspection report to the customer. For each order, no matter its quantity and value, our quality control departemnt will make strict inspection before delivery, the inspection contents include apperance, tolerance, dimension, mark, special requirements of customers, etc. To guarantee our steel materials sent to the customer is qualified.

Advantages of ASTM A573 structural carbon steel, ordinary carbon killed steel plate: there is no gas in the steel plate, the impurity is relatively small, the stress is very uniform, and it has good welding performance. It is widely used in parts with high requirements. Disadvantages of ordinary carbon killed steel plate: the surface quality of the killed steel plate is not as good as that of boiling plates, there are concentrated shrinkage holes, and the killed steel plate price is more expensive.

Processing performance of quenched and tempered steel: ASTM A573 structural carbon steel plate can be used for cold working, bending and cutting. When the gas is cut off, cracks will not occur even without preheating. When preheating processing, quenched and tempered steel needs to be processed below the tempering temperature. Superb wear and corrosion resistance: Because it contains alloy elements such as copper and chromium, it has good corrosion resistance, higher hardness, and good wear resistance compared with ordinary steel.

In the year of 2015, customer from Peru oil refinery contact with us from Internet. After one month’s negotiation and quotation, they chose us as there supplier of raw steel plate ASTM A573 structural carbon steel grade ASTM A36. We get an trail order of 300 tons in April. When the first ship arrived, they inspect the steel plate and very happy with the quality we supply. Then they put another 1700 tons order, we sent to them within 90 days. Our company management group visit the customer in the beginning of 2016 and the visit is very successful.

Leave A Comment