Our team is a dynamic, but also mature and steady team. The talents are made of different ages. There are experienced ones, and also creative ones, that also makes our company culture diversified. We have complete department structure, to make the whole work procedure run smoothly. For every step, we have special person to be in charge and responsible for our customer and update information to the customer in time. So you just need not worry too much to purchase steel materials from our company.

Generally, in the process of selecting SA573 Grade 65 carbon steel structural plate, automobile steel plate manufacturers, the most important thing is to look at the appearance and thickness of automobile steel plates produced by manufacturers. Generally, the appearance of good SA573 Grade 65 carbon steel structural plate, automobile steel products is relatively fine, there are no obvious defects on the surface of automobile steel plate, and the thickness of automobile steel plate is within the specified range value. These are very important factors to measure the production capacity of the manufacturer and the quality of automobile steel plate products.

Q245R boiler steel plate introduction: Q is the first letter of "Qu" Chinese Pinyin; Number 245 is the yield strength value; R: is the first character of "Rong" Chinese Pinyin. Q245R steel is a special plate for pressure vessels and boilers with a yield strength of 245MPa. It has outstanding mechanical properties and processability. If you have special requirements, our company can supply Z15, Z25, Z35 and other Z performance tests.

The preparation of SA573 Grade 65 carbon steel structural plate galvanized steel before welding is the same as that of ordinary low-carbon steel. It is necessary to carefully handle the groove size and nearby galvanized layer. In order to achieve penetration, the groove size shall be appropriate, generally 60 ~ 65 °, with a certain gap, generally 1.5 ~ 2.5mm; in order to reduce the penetration of zinc into the weld, the galvanized layer in the groove can be removed before welding. In the practical work, the centralized beveling, no blunt edge technology for SA573 Grade 65 carbon steel structural plate centralized control, two-layer welding process, reducing the possibility of incomplete penetration.

The SA573 Grade 65 carbon steel structural plate pressure vessel steel plates are our featured products. We have supplied pressure vessel steel plates to tank manufactures, boiler makers, power plants and so on customers all over the world. We have online service for you at any time, welcome to contact and learn more information about pressure vessel steel, such as SA573 Grade 65 carbon steel structural plate ASTM A537 class 1 equivalent, 16Mo3 datasheet, Q245R material properties, Q345R material specification, P355GH properties, pressure vessel steel price, etc.

Company through its own SA573 Grade 65 carbon steel structural plate website, multimedia, radio, newspapers, the group, the handbook of the corporate culture carrier, approved and publicity column, in-depth to carry out enterprise culture construction, also through photography, painting, calligraphy, cartoon, speech, and the songs of the enterprise design, various cultural and sports activities to carry out enterprise culture construction.

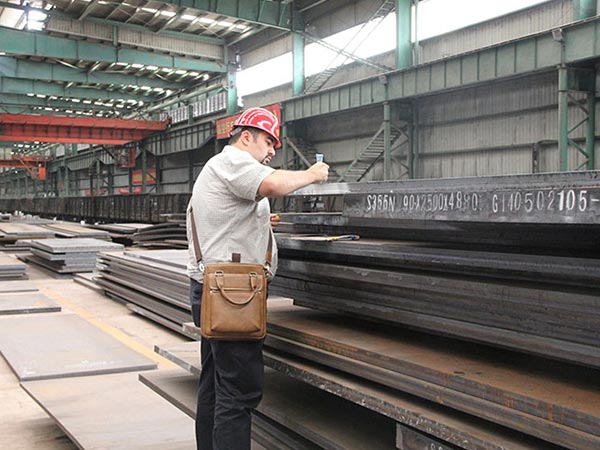

When providing technical services on site, the after-sales personnel shall strictly abide by the safety rules and regulations of the construction site, consciously take safety protection measures (such as wearing safety helmet when entering the construction site), accept the supervision and management of the site; without permission on the construction site, they shall not dismantle, smear or damage any goods; the commissioning of contract goods shall be carried out under the supervision of the site supervisor If necessary, it shall be approved by the site supervisor or the person in charge of the project department.

Leave A Comment