The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the a

The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the a

The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the after-sales service adopts regular return visit for customers. Timely understand the customer's satisfaction with our products, and solve the user's problems at any time.

Wear resistant steel is very wear-resistant: for example, excavator bucket, long-term excavation requires good wear resistance. Wear resistant steel has a very high hardness: for example, scraper conveyor, if the hardness is not up to standard, it is extremely easy to fracture, resulting in very serious consequences. Wear resistant steel has good corrosion resistance: many equipment need to transport chemical corrosion products, so corrosion-resistant mechanical equipment is needed. A36 steel and A573 Grade 58 steel supplier, Wear resistant steel has good fatigue resistance: such as bearing steel ball, which can do fast and repeated movement, and need to guarantee performance.

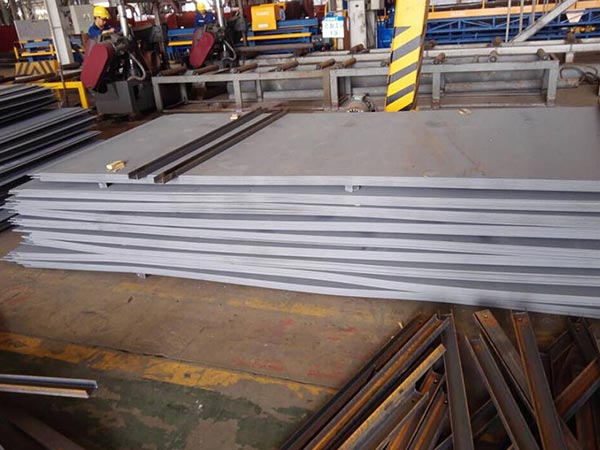

Rolling of steel plates is the core of the entire steel rolling production process. The billet is deformed by rolling. The rolling process plays a decisive role in product quality. The quality requirements of rolled A36 steel and A573 Grade 58 steel supplier products include the three aspects of product geometry and dimensional accuracy, internal organization and performance, and product finish. Finishing: It is the last process in the A36 steel and A573 Grade 58 steel supplier rolling process, and it is also a more complicated process. It plays a final role in guaranteeing the quality of the product.

We cooperated with the Peruvian government for many years. And supply them large diameter steel pipes and pipe fittings to support their Hydropower Station Projects. We do 100% UT, RT, Hydraulic test and so on tests for the A36 steel and A573 Grade 58 steel supplier steel pipes. And do PT, MT and so on tests for the pipe fittings. We published "Welding Procedure Qualification report" after production. And our mill will keep the test record in the documentary department for 5 years. If meet any problems in following application, we can check the test record easily and assist to solve problems at the first time.

Leave A Comment