The main applications of normalizing are as follows:①For low carbon steel, a656 steel hardness. The hardness of low carbon steel after normalizing is slightly higher than that after annealing, and the toughness is also better, so normalizing can be used as the pretreatment of cutting.②For medium carbon steel, normalizing can be used as the final heat treatment instead of quenching and tempering treatment, or as the preparation treatment before surface quenching by induction heating.③Normalizing can be used in tool steel, bearing steel, carburizing steel and so on, which can eliminate or inhibit the formation of network carbide, thus obtaining the good microstructure needed for spheroidizing annealing.④Normalizing can refine the cast structure and improve the machinability of steel castings.

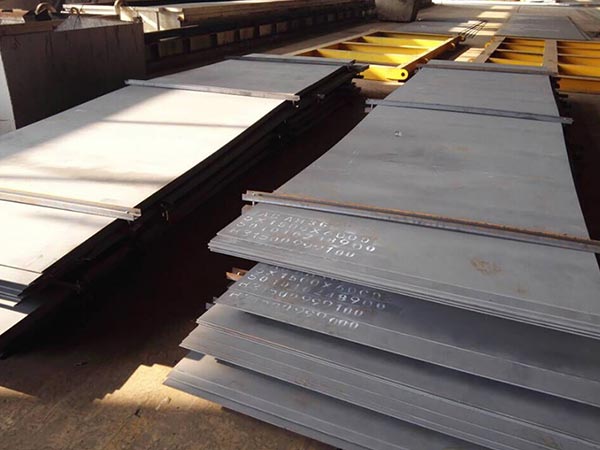

The company manages NM400 wear-resistant plate, NM450 wear-resistant plate, a656 steel hardness, NM500 wear-resistant plate and other wear-resistant plate products. The wear-resistant plates are widely used in many industries, such as engineering, mining, cement, power, construction, machinery, coal, glass manufacturing, paper making, metallurgy, petrochemical, etc.. And the wear-resistant plates are also used in wheel device, grab equipment, bucket body, edge, lining plate, hopper, funnel, bucket valve, etc. parts.

The company focuses on teamwork and builds a team with a dream. For society: we focus on quality first, integrity-based, service-oriented create value for customers and wealth for the society. For employees, the company promote healthy living, happy work, unity, innovation. For working, we seek the efficient operation, the pursuit of excellence. Welcome to come, visit our office building and join us.

The company strengthens process management and pays attention to assessment. One of the key points of good service is to strengthen the process management and improve the evaluation mechanism. Make the after-sales service system more perfect and provide better service for customers.

Our vasion is to create a first-class steel plate manufacturing enterprise with international competitiveness. Business Vision: Improve value with quality and become the leader in the industry. Core values: people-oriented, integrity, responsibility, excellence. Development strategy: Seek development through science and technology, and seek benefits from management. Besides, we will create a harmonious business atmosphere, unblock the channels for employees to communicate, and build a stage for various sports and talents.

For ASTM A573 Grade 70/A573 Gr.70 carbon manganese silicon steel plates, our company would issue the original mill test certificate a656 steel hardness EN 10204 3.1 for clients when arrange delivery, so that clients can trace the A573 Gr.70 plates origin easily.

Leave A Comment