Our company is a specialized technical support and after-sales service organization - customer service center. At the same time, we have provided excellent technical A573 Grade 65 section steel personnel and strong technical support for our company, and cultivated an excellent after-sales team for our company. Our company will appoint a full-time service manager to be responsible for the unified coordination of technical support and A573 Grade 65 section steel after-sales service of the project.

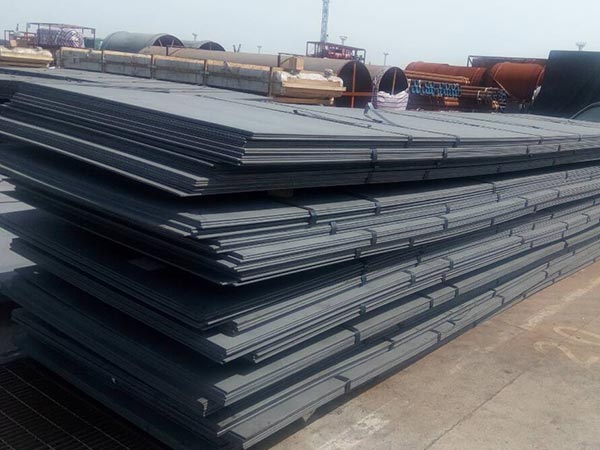

A573Gr70 plate technical conditions: the chemical composition and mechanical properties of A573Gr70 steel are produced in line with ASTM A573. When ordering, additional impact, flaw detection, z direction, composition control, performance requirements beyond the standard can be added. Available heat treatment processes of A573 Grade 65 section steel, A573Gr70 plate: hot rolling, controlled rolling, normalizing, tempering, quenching, normalizing + tempering. Our company supply flaw detection Z15-Z35 thickness direction performance.

Hot Rolled Plates A573 Grade 65 section steel MachiningAfter final forging/forming and Heat treatment process, all the pipe Fittings, Flanges, Fasteners, Etc. are sent for machining i.e. and preparation, O/D and I/D matching as per dimensional codes. An Expert Q.C. engineer is involved and he keeps constant vigil on every machining operation. Step machining is carried out as required by the codes. GO and NO-GO gauges are used to check the O/D & I/D of the fittings, Flanges, etc.

The preparation of A573 Grade 65 section steel galvanized steel before welding is the same as that of ordinary low-carbon steel. It is necessary to carefully handle the groove size and nearby galvanized layer. In order to achieve penetration, the groove size shall be appropriate, generally 60 ~ 65 °, with a certain gap, generally 1.5 ~ 2.5mm; in order to reduce the penetration of zinc into the weld, the galvanized layer in the groove can be removed before welding. In the practical work, the centralized beveling, no blunt edge technology for A573 Grade 65 section steel centralized control, two-layer welding process, reducing the possibility of incomplete penetration.

The company conducts periodic and targeted training and guidance for after-sales service personnel. As the saying goes, "no one is perfect, no gold is red", to help after-sales service personnel improve service skills and correct service attitude. Carry out relevant technical training for after-sales service personnel, so that after-sales service practitioners have professional product knowledge.

The company has always adhered to the corporate purpose of “improving benefits, creating wealth, benefiting employees, and giving back to the society”. We adhere to the corporate spirit of ""innovation, efficiency, integrity, and win-win"", attract first-class talents, strive for first-class indicators, create first-class benefits, build first-class enterprises, pursue excellence, innovative development, and efficiently serve the coordinated development of the Beijing-Tianjin-Hebei and the ""Belt and Road"" Economic development strategy.BEBON is willing to cooperate with friends from all sides for a win-win development!

Leave A Comment