When talking about our team, it is hard not to mention our QC department (Quality Control). We have built strict qualitycontrol system to guarantee the steel quality. During the steel materials production, we have strict monitoring measures and indicators, and ensure no chemical composition, mechnical properties and so on technical problems for the steel materials A573gr.65 inspection. After production, our QC department will conduct another inspection regarding to the steel quantity, dimension, mark and so on points before delivery.

S45C steel plate chemical composition: C 0.42~0.48, Si 0.15~0.35, Mn 0.60~0.90, P≤0.030, S≤0.035, Cu≤0.30, Ni≤0.20, Cr≤0.20Mechanical properties of A573gr.65 inspection productTensile strength>686MPaYield strength>490MPaElongation δ5>17%Shrinkage ψ>45%Impact toughness value>78J/cm2The hardness is 201~269HB.

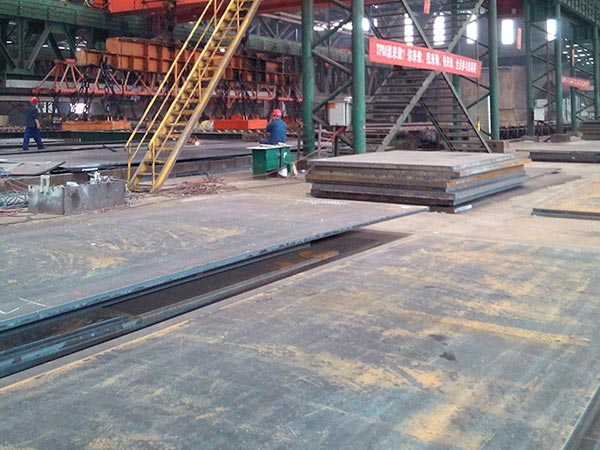

Hot rolled A573gr.65 inspection product stock size: 12*1600*91000, 25*1950*10250, 25*1950*10150, 14*2000*10000, 12*1600*10000, 16*1500*9340, 60*2020*6100, 25*1950*9700, 14*2000*13500, 75*2390*4320, 16*1500*9340, 50*2740*13460, 20*2100*10700, 20*2500*6200, 60*1750*9100, 34*1900*12000, 12*2050*5100, 45*2010*10000, 25*2100*8650, 70*2270*7600, 16*1500*9340, 6*1950*10000, 30*2000*7630, 20*2100*11600, 70*2260*7950, 34*1900*12000.

In actual processing applications, the processing A573gr.65 inspection thickness of flame cutting ranges from 6 to 200 mm, and the A573gr.65 inspection cutting thickness can even reach 350 mm by replacing the air pipe and cutting torch nozzle. In order to better improve the cutting quality, the related process parameters will be slightly different when using flame cutting for materials of different thickness. The verticality of the cutting surface processed by the CNC flame cutting machine is generally high, and the slope can be controlled below 2-3°. The characteristic is that flame cutting performs better when cutting A573gr.65 inspection with a certain thickness above 10mm.

We should help solve the customer's problems in time, not just verbally, without solving the problems or shirking the responsibility. Improving after-sales efficiency can make customers feel respect. We should take their problems seriously and show sincerity. It can also give customers a good impression and reduce the negative impact.

Our company was founded in 2009, and has been committed to steel business since its establishment. Over the years, the company's performance shows a good development trend, with a wide range of customers in the government, domestic and foreign markets. The company has always been in line with the tenet of "based on trust and win with quality", focusing on the market demand, with a long-term vision, with years of hard work and trustworthy operation, and the support of the majority of A573gr.65 inspection businesses and customers, has won the unanimous praise and trust of the industry and customers!

Leave A Comment