The company has a group of experienced steel plate continuous processing line construction, production management, operation and professional and technical personnel. The company is a modern enterprise integrating scientific research and development, production processing, sales and service. Our main products include hot rolled plates, seamless pipes, A633 Gr E factory and steel structures. At the same time, it also adheres to international standards and adheres to the international line.

In 2019, the output of pig iron in the world was 1.265 billion tons, with China accounting for 64%; the overseas output accounted for 36% (460 million tons), ranking 86.982 million tons of EU 28 countries, 74.907 million tons of Japan, 74.099 million tons of India, 73.264 million tons of CIS, and A633 Gr E factory 47.521 million tons of South Korea. In the first quarter, the global output was 311 million tons, with a year-on-year decrease of 0.5%, with China A633 Gr E factory increasing by 2.4%; the overseas output decreased by 5.4%, Among them, EU decreased by 9.2%, Japan increased by 1.3%, India decreased by 7.7%, CIS increased by 2.1%, and South Korea decreased by 4%.

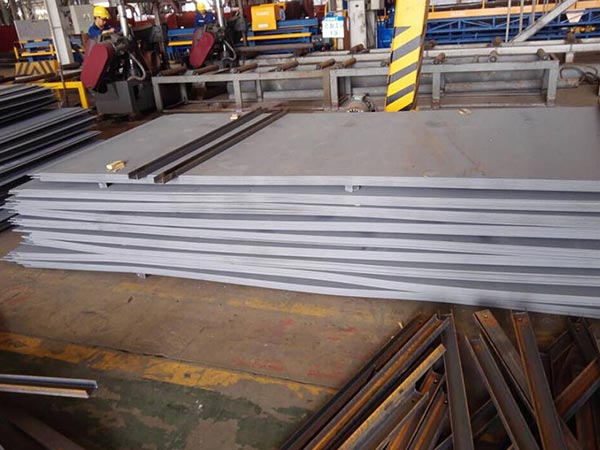

Common carbon killed steel plates are steel plates made by hot-rolling ordinary carbon structural steel killed billets. The advantage of A633 Gr E factory, killed steel is that the chemical composition is uniform, so the mechanical properties of each part are also uniform, the welding performance and plasticity are good, and the corrosion resistance is strong. Common killed steel plates are mainly used to produce components that withstand impact at low temperatures, welded structures and other structural parts that require higher strength.

Japan is a typical shipping first, and its raw materials are imported from Oceania, central and South America and other Asian countries. Most of the A633 Gr E factory steel produced is exported to China and other Asian countries, and a small amount is exported to America. Shipping is the main way of its A633 Gr E factory steel international transportation. According to the data, steel goods account for about 20% of the total sea freight in Japan. The domestic transportation of Japanese steel is mainly truck.

Blast furnace ironmaking is a traditional ironmaking method based on coke energy. It cooperates with converter steelmaking and is the main method of producing A633 Gr E factory steel at present. This dominance of blast furnace ironmaking is not expected to change for quite a long time. The essence of blast furnace ironmaking is the reduction of iron. Besides, coke is used as fuel and reducing agent. At high temperatures, iron ore or iron-containing raw materials are reduced from an oxide or mineral state to liquid pig iron.

In addition to quality assurance, service is also important for the competition of steel suppliers. All the after-sales service personnel of the company have received professional training and assessment. The steel products supplied by our company enjoy the life-long quality problem replacement service. In the process of using our steel A633 Gr E factory products, if there is any problem, just contact us in time, and our after-sales service personnel will look for countermeasures and solve the problem with you as soon as possible.

Leave A Comment