Our after sales department is an very important part of our department structures. After the customer receive steel materials, our after sales department will follow up regularly and solve problems for them in time if they have the needs. We romise to return the goods for free for its lifetime if it is quality of the steel material itself. Meanwhile, if you have any advice or complaints, also welcome to feed back to our after sales department, and we are trying to give better service to you.

Boiler steel plate A633 Grade E steel quality mainly refers to the hot-rolled medium and heavy plate materials used to manufacture superheater, main steam pipe and heating surface of boiler fire chamber. The main boiler steel materials are high-quality structural steel and low-alloy heat-resistant steel. Common boiler steel includes low-carbon killed steel A633 Grade E steel quality smelted in open furnace or low-carbon steel smelted in electric furnace, with carbon content WC in the range of 0.16% - 0.26%.

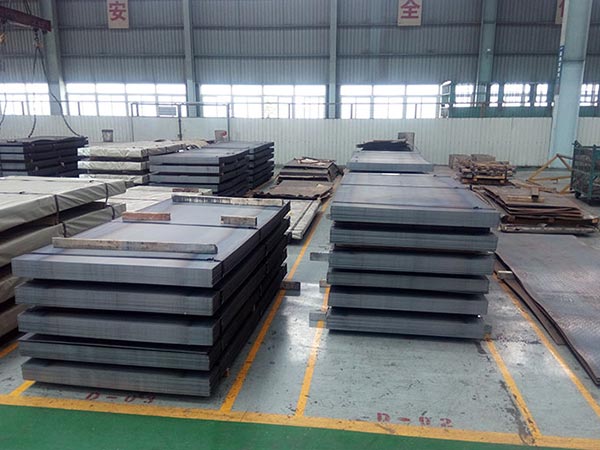

Standard: AISI,ASTM,BS,DIN,GB,JISMaterial Grade: ASTM A36, A283Gr.C, SS400, SPHC ,Q235B, Q345B, S235JR, S275JR, A633 Grade E steel quality, S355J0, P235GH,P265GH,P395GH,P355GH,16Mo3, P275NH/NL1/NL2, P460NL1Thickness: 1.5-200mmWidth: 1000-3000mmLength: 1-12mSurface treatment: Coated or Blasting and painting Quality: MTC will be provided with goods, third part inspection is acceptable, for example BV, SGS.

In actual processing applications, the processing A633 Grade E steel quality thickness of flame cutting ranges from 6 to 200 mm, and the A633 Grade E steel quality cutting thickness can even reach 350 mm by replacing the air pipe and cutting torch nozzle. In order to better improve the cutting quality, the related process parameters will be slightly different when using flame cutting for materials of different thickness. The verticality of the cutting surface processed by the CNC flame cutting machine is generally high, and the slope can be controlled below 2-3°. The characteristic is that flame cutting performs better when cutting A633 Grade E steel quality with a certain thickness above 10mm.

The company strengthens process management and pays attention to assessment. One of the key points of good service is to strengthen the process management and improve the evaluation mechanism. Make the after-sales service system more perfect and provide better service for customers.

[Enterprise Spirit]: professional, honest, dedicated and innovative.[Enterprise Tenet]: provide customers with satisfactory steel products and services.[Enterprise Policy]: customer satisfaction is our pursuit. The trust of customers is our achievement.[Service Tenet]: to develop the market with quality and grow with sincerity.The company adheres to the commitment of quality first and customer foremost, takes high quality and high efficiency as the service principle, takes mutual benefit and common development as the business purpose.

Leave A Comment