For employees' development, the company's transformation and development provides employees with a broad career development platform. The company needs "lion-type" entrepreneurial leaders who are full of entrepreneurial enthusiasm and

For employees' development, the company's transformation and development provides employees with a broad career development platform. The company needs "lion-type" entrepreneurial leaders who are full of entrepreneurial enthusiasm and

For employees' development, the company's transformation and development provides employees with a broad career development platform. The company needs "lion-type" entrepreneurial leaders who are full of entrepreneurial enthusiasm and dare to self-renovate. They also need a large number of professional and professional high-quality talents, and employees can get full capacity to display opportunities.

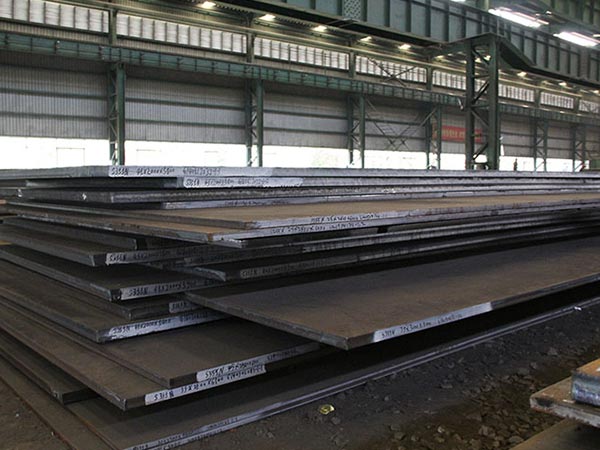

EN10025-2 S355K2 is a non-alloy steel quality with 355Mpa minimum yield strength when thickness ≤16mm. It takes low temperature impact testing at -20℃ with minimum energy 40J. For the advantage of S355K2 steel plate, astm a656 grade 80 welding, it offers good weldability with conventional welding processes. In addition to their good mechanical properties, structural steels also have very acceptable toughness values. S355K2 steel plates are widely used in low temperature surroundings such as ice river, deep oceans.

As to the Chemical composition, the different content is a main on carbon content, while the carbon content of astm a656 grade 80 welding, A283Gr. D is no more than 0.27% and it is higher than Grade C (≤0.24%) ; as to the mechanical property, the differences are tensile strength and yield strength, while the tensile strength of ASTM A283 Gr.D is 415-550MPa (60-80 ksi) and yield strength of ASTM A283 Grade D is 230MPa (33 ksi).

The hot rolling method is to heat the astm a656 grade 80 welding steel material to about 1000 ℃ ~ 1250 ℃ and use the rolling mill to roll it. The traditional hot rolling process is generally divided into the following two steps: the first step is to use the primary rolling mill or billet rolling mill to roll the ingot, billet or continuous casting billet into a certain shape and size of billet. This kind of astm a656 grade 80 welding rolling process is usually called semi-finished product production, also called blank production.

Our company has established and constantly improved the customer service system and emergency response system. Through the customer service management system, we track the service of the after-sales service team and provide efficient and standard services in time. At the same time, the company formulates a regular return visit system, compares the historical cases of customer problems, proposes a pre solution, and ensures that the service is in place in a short time.

Firmly establish the "people-oriented, safe development" concept, strictly follow the safety production policy of "safety first, prevention first, comprehensive management", strengthen and improve the management and supervision of safety production in an all-round way, and strive to improve the controllability of safety management And effectiveness, cultivate safety culture, improve long-term safety production mechanism, and build a harmonious BEBON.

Leave A Comment