Our company attaches great importance to technical support and after-sales service, and has established a customer service center to provide unified technical support and service for A573 Gr.70 steel and A517 Grade A steel comparison various engineering projects. Customer service center has a strong technical force of technical service team, composed of a customer service center manager, several A573 Gr.70 steel and A517 Grade A steel comparison after-sales service personnel, responsible for unified acceptance and processing of local after-sales service needs.

A573 Gr.70 steel and A517 Grade A steel comparison and so on steel structure engineering steel has good plasticity, which can make the structure have obvious deformation before being destroyed, so as to avoid brittle failure of structure. The good plasticity of steel can adjust the local peak stress to redistribute the stress, and improve the ductility of components, so as to improve the seismic capacity of the structure. The impact toughness of A573 Gr.70 steel and A517 Grade A steel comparison and so on steel structure engineering steel is good, which can improve the ability of resisting dynamic load and avoid the occurrence of cracks and brittle fracture.

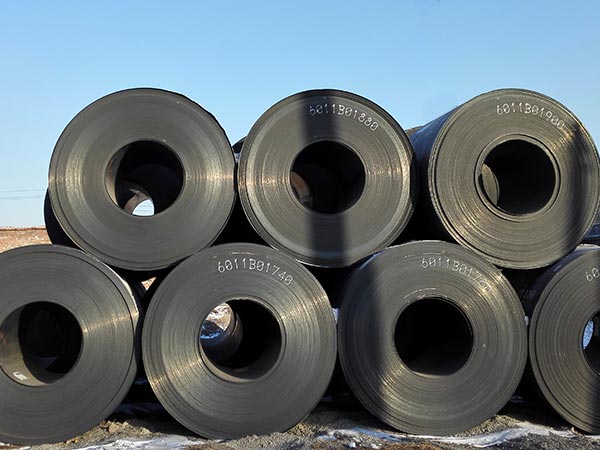

Steel transportation because of the special material of A573 Gr.70 steel and A517 Grade A steel comparison steel, is a metal with "iron" as the main basic element, small volume and large weight, and easy to oxidize and rust when contacting with air and rain water, so there are many precautions in the transportation of steel. There are 11 proverbs for steel transportation: "evenly placed, moisture-proof and rust proof". Our company chooses the logistics aspect to be very rigorous, takes the customer's request as the standard, guarantees the steel product quality.

Weathering steel generally adopts the process route of fine material into the furnace-smelting (converter, electric furnace-microalloying treatment-argon blowing-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and cooling. The scrap steel is added into the furnace together with the charge, and smelted according to the conventional process. After the A573 Gr.70 steel and A517 Grade A steel comparison steel is tapped, deoxidizers and alloys are added. After the molten steel is treated with argon blowing, the molten steel is cast. By adding rare earth elements to the steel, the A573 Gr.70 steel and A517 Grade A steel comparison weathering steel is purified and the content of inclusions is greatly reduced.

Leave A Comment