The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the a

The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the a

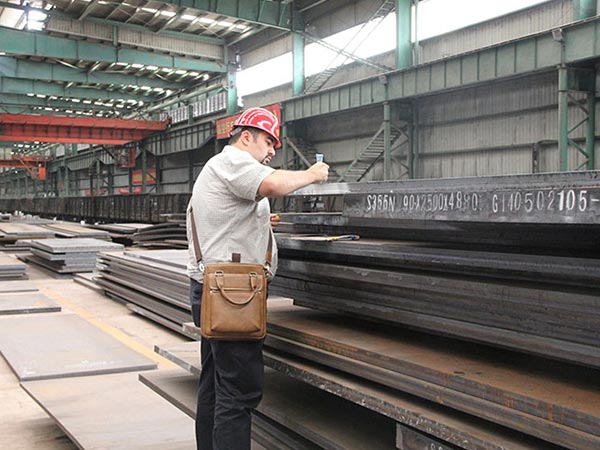

The company has a perfect after-sales service system and quality assurance system. The company adheres to the service principle of "all for users", and has established a professional after-sales service team. In the future service process, the after-sales service adopts regular return visit for customers. Timely understand the customer's satisfaction with our products, and solve the user's problems at any time.

According to the separate performance report released by India's Jindal stainless steel (Sisal) Co., Ltd. (JSHL), as of March 31, 2020, due to the global economic slowdown, epidemic situation, imports and other factors, its astm a656 grade 80 welding stainless steel sales decreased by about 10% to 600000 tons from 667000 tons in the previous fiscal year, and its net sales decreased by nearly 7% to 83.396.9 billion rupees, with the same gross operating profit (EBITDA) After tax profit increased by 22.4% to 3.203 billion rupees. The adoption of the new tax system has a positive impact of RS 220 million on after tax profits.

The surface of alloy steel coil is specially treated during processing. The wear resistance of steel coil and plate made of alloy steel is much better than that of traditional rolling plate, and the cost is also low. The heat resistance and high temperature resistance of alloy steel coil is better than that of traditional rolling plate, and it will not deform easily. Besides, the strength of the astm a656 grade 80 welding, alloy steel is very high, it is not easy to break and can be used for a long time.

The company attaches great importance to logistics services, sets up our own transport truck fleet, improves customer response capacity through the improvement of logistics capacity, and further reduces costs. Customers ordering astm a656 grade 80 welding steel from our company can not only enjoy the service of fast delivery, but also enjoy lower transportation costs. Fast, accurate, simple and efficient has always been our principle.

Both the cross rolling method and the extrusion method must first heat the tube blank or ingot, and the steel tube produced is called hot rolling tube. Steel pipes produced by hot working can sometimes be cold worked as required. There are two methods of cold working: one is cold drawing, that is, drawing the astm a656 grade 80 welding steel pipe through the drawing die to make the steel pipe gradually thin and elongate; the other is cold rolling, which is the method of applying the hot rolling mill invented by the menesmann brothers to cold working. The cold working of astm a656 grade 80 welding seamless steel pipe can improve the size accuracy and finish of steel pipe, and improve the mechanical properties of materials.

Our company has established and constantly improved the customer service system and emergency response system. Through the customer service management system, we track the service of the after-sales service team and provide efficient and standard services in time. At the same time, the company formulates a regular return visit system, compares the historical cases of customer problems, proposes a pre solution, and ensures that the service is in place in a short time.

Leave A Comment