The mechanical properties of hot rolled steel plate are far less than that of cold working and forging, but the A573 Gr.65 steel and P355N steel comparison, hot rolled steel plates have better toughness and ductility. Cold rolled steel plate has a certain degree of work hardening and toughness is low, but it can achieve a better yield ratio, and can be used for cold bending spring leaf and other parts. At the same time, because the yield point of cold rolled steel plate is close to the tensile strength, the danger is not foreseen in the use process, and accidents are prone to occur when the load exceeds the allowable load.

Mechanical properties of 45# steel high-quality carbon structural steel: Tensile strength σb (MPa): ≥600, yield strength σs (MPa): ≥355, elongation δ5 (%): ≥16, section shrinkage ψ (%): ≥40, impact energy Akv (J): ≥39. 45# steel impact toughness value αkv (J / cm2): ≥49 (5), hardness: unheated, ≤229HB; annealed steel, ≤197HB. A573 Gr.65 steel and P355N steel comparison, 45# steel chemical composition % (Carbon: 0.42 to 0.50, Silicon: ≤0.40, Manganese: 0.50 to 0.80, Sulfur: ≤0.045, Phosphorus: ≤0.045, Chromium: ≤0.40, Nickel: ≤0.40, Molybdenum: ≤0.10).

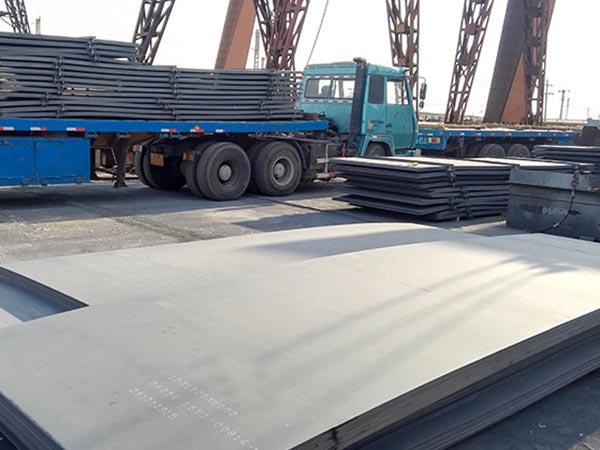

The yield rate is a comprehensive technical and economic index in the production of medium and heavy plates such as A573 Gr.65 steel and P355N steel comparison. Increasing the yield rate can not only reduce the loss of metal, but it is also vital to the economic benefits of the steel enterprise. The influencing factors of the yield of medium and heavy plates are various, for example, the variety structure, negative deviation rolling level, plate shape control level, cutting loss, rolling waste and burning loss, etc.

Plasma cutting has a wide range of applications. With different working gas, it can cut various kinds of metals that are difficulty to handle by oxygen cutting. Plasma cutting is fast and efficient when cutting metal with small thickness. The A573 Gr.65 steel and P355N steel comparison cutting speed can reach more than 10m/min. Plasma cutting can get a clean, neat, non stick slag cutting surface, while the deformation and thermal effect of the incision are small, its hardness change is little, and the cutting quality is good.

Leave A Comment