The development SA573 Gr.58 cold rolled technique of the company comes from the resource advantage, service advantage, logistics advantage and brand advantage established over the years, and it is also inseparable from the full support of new and old customers. We will uphold the support of all sectors of society, actively provide users with SA573 Gr.58 cold rolled technique high-quality and efficient services, work together for win-win, and create a better tomorrow!

In the process of SA573 Gr.58 cold rolled technique steel transportation, enterprises often use railway transportation, highway transportation, water transportation and other ways to transport. According to the cargo owner's requirements on the timeliness of the goods and the different transportation routes, our company will choose SA573 Gr.58 cold rolled technique different modes of transportation. According to the specific needs of customers, or specify the mode of transportation.

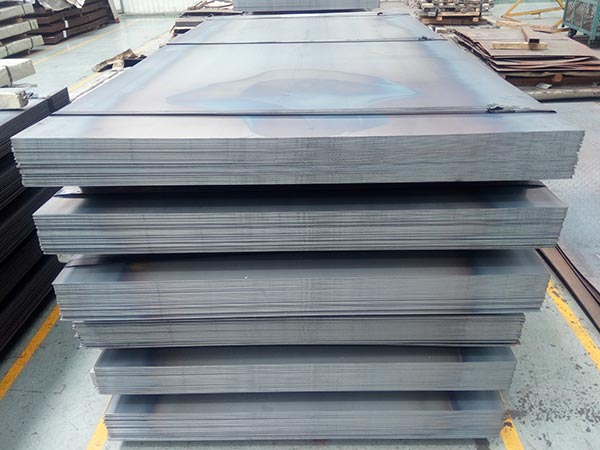

Medium and high carbon alloy hot rolled plates are mainly used in cold rolling and calendering, saw blades and tool industries. The company has taken advantage of smelting, hot rolled SA573 Gr.58 cold rolled technique plate and coil finishing equipment and technical advantages, and has successfully developed a batch of high-carbon and its alloy steel and medium-carbon high-alloy SA573 Gr.58 cold rolled technique steel hot-rolled coils with the goal of replacing imports. The iron oxide scale is delivered and trusted by high-end users.

Good news: In May 17th, 2018, the Myanmar navy's local representative visit our office and hot rolled plate production line, and sign another contract 2025 tons LR A shipbuilding steel plates SA573 Gr.58 cold rolled technique order in our office. With the fast development in Myanmar, Myanmar navy build frigate every year. Bebon cooperated with Myanmar Navy company from from 2015. They purchased 412 ton LR AH36 ship steel plate from Bebon as trial order in 2015. After receiving the goods, they speak highly of the quality and bebon's service. After that they purchase the shipbuilding steel plate from bebon regularly.

According to GBT3077, 42CrMo steel chemical composition should be within the range (%): 42CrMo carbon content is 0.38-0.45 (C), Silicon content is 0.17-0.37 (Si), Manganese content is 0.50-0.80 (Mn), Chrome content is 0.90-1.20 (Cr), Molybdenum content is 0.15-0.25 (Mo). The high Cr content contrivutes to high strength of 42CrMo steel, with min. yield strength of 930 Mpa, and min. tensile strength of 1080 Mpa. The common heat treatment for SA573 Gr.58 cold rolled technique, 42CrMo steel is quenching and tempering.

We have a stable system and professional human resource management work as the support, from the six aspects of guidance, cohesion, incentive, constraint, radiation and stability, we continue to introduce, modify and train employees from concept to action, and shape employees through constant guidance of common values.

Leave A Comment