The company regularly holds sales elites to share experiences, to promote the rapid growth of colleagues, and achieve the company and employees. The company conducts employee skill training and related knowledge video learning from time to time. All these things is to improve the employees' skills and literacy, and reflects its own value. It has always been the pursuit of BBN steel to enhance the employee’s ability and keep up with the times.

Recently, a symposium on the celebration of the 70th anniversary of the founding of the People's Republic of China by the iron and steel industry was held in Beijing Convention Center. The 2019 Year of the Pig is the 70th anniversary of the founding of the People's Republic of China. Growing up with the motherland, BBN a633 grc Steel Staff sang songs to the mark the 70th victory anniversary. In the last of September, Henan BBN Steel organized all employees to sing ""My Country and I"" and made a film.

Low-alloy steel plates have low carbon content, and because ferrosilicon is not used for deoxidation, the silicon content in steel is often <0.07%. The outer layer of rimmed steel is crystallized in a rimmed state, so the surface layer is pure and dense, the surface quality is good, and the Zhengzhou low alloy steel plate a633 grc has good processing performance. Rimmed steel does not have large concentrated shrinkage cavities, uses less deoxidizer, and the cost of steel is low.

In particular, the EU imports a large amount of iron ore from central and South America and Oceania, which are mainly transported by sea. The perfect port infrastructure makes the port operation cost of EU iron ore raw materials import relatively low. However, the a633 grc steel transportation between EU Member States is mainly railway transportation, and the EU member states have established a very developed railway network and railway information infrastructure.

Preheating cutting: The most effective way to prevent steel plate cutting cracks is to preheat before cutting. Before flame cutting, the steel plate is usually preheated, and the preheating temperature mainly depends on the quality level and thickness of the steel plate. The preheating method can be carried out with flame burner, electronic heating pad, or heating furnace. In order to determine the preheating effect of the steel plate, the required temperature should be tested at the heating point.

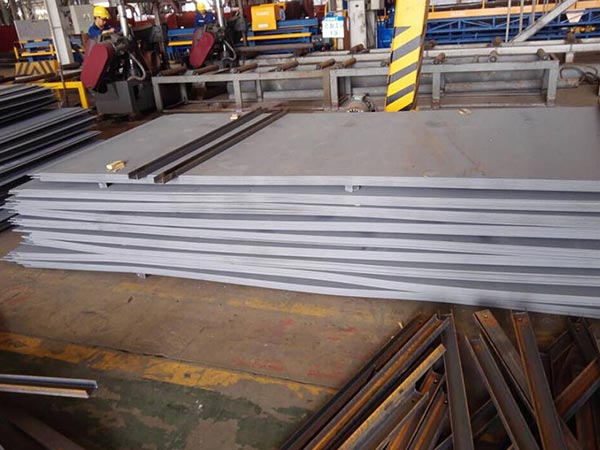

Before delivering our hot rolled plate product we apply various tests to check the quality of carbon steel a633 grc plates such as- mechanical test, chemical test, hardness test, toughness test, eddy current test, impact test, micro test, flaring test, flattening test, etc. We are provided best packing for structural steel plates to avoid rust. Our after-sales service team will contact you if you have any question.

Leave A Comment