The company has superior geographical location and convenient transportation. After more than 20 years of market trials and tribulations, from small to large, from weak to strong, in order to meet the needs of customer extension development, the company expanded the deep A36 carbon steel angle bar processing services of cutting steel pieces. Now we have built a business system integrating steel plate, steel plate cutting and A36 carbon steel angle bar steel deep processing. The company provides one-stop solution for customers with lower price, higher quality and faster response speed.

VLE460 steel plate grade analysis: "VL" stands for the abbreviation of "DNVGL", which is the standard certified by the two classification societies of DNV (Norway) and GL (Germany). VL E460 hull steel characteristics: good welding and other properties. It is suitable for repairing ships and main structures of naval vessels. Naval steel is required to have higher strength, better toughness, blast resistance and resistance to deep water collapse.

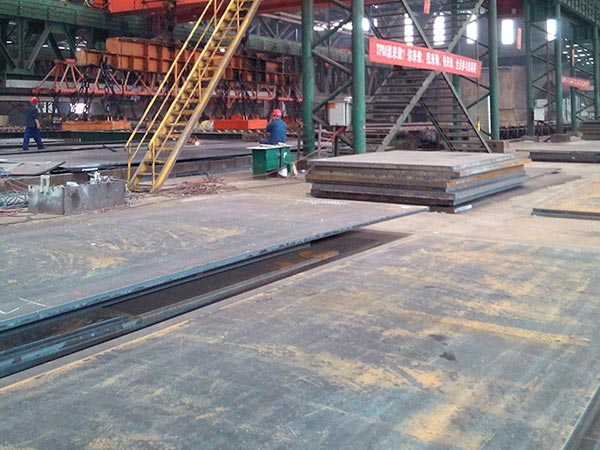

Wear resistant steel plate has high wear resistance and good impact performance. It can be cut, bent, welded, etc. This material A36 carbon steel angle bar can be connected with other structures by welding, plug welding, bolt connection, etc. Wear resistant steel plate has the advantages of saving time and convenience in the process of maintenance. It is widely used in metallurgy, coal, cement, electric power, mining, building materials and other industries. Compared with other materials, wear resistant steel plate has a high cost performance, and has been favored by more and more industries.

The final heat treatment of quenched and tempered alloy steel, A36 carbon steel angle bar is quenching and high temperature tempering. The hardenability of quenched and tempered alloy steel is high, and oil is generally used. When the hardenability is very high, it can even be air cooled, which can reduce the defects of heat treatment. The final properties of quenched and tempered alloy steel depend on tempering temperature. Generally, it is tempered at 500 ℃ - 650 ℃. The required properties can be obtained by selecting tempering temperature. In order to prevent the second kind of temper brittleness, fast cooling (water cooling or oil cooling) after tempering is beneficial to the improvement of toughness.

P235GH steel material number under EN10028-2:2003 standard is 1.0345. This steel is a European pressure vessel steel. P235GH Mechanical properties: Tensile strength σb (350 ~ 480 MPa); Yield strength σs(215 MPa min.); Elongation ≥25%; Brinell hardness ≤105 ~ 140. A36 carbon steel angle bar, P235GH steel chemical composition (mass fraction,%): ≤0.16 C; ≤0.35 Si; 0.60 ~ 1.20 Mn; ≤0.025 P; ≤0.010 S; ≤0.30 Cr; ≤0.30 Ni; ≤0.30 Cu; ≤0.08 Mo; ≤0.02 V; ≤0.02 Nb; ≤0.012 N; ≤0.020 Al; ≤0.03 Ti.

our company is leading supplier of API 5CT casing pipes in China. N80 oil casing pipes enjoy high size precision, good weld toughness, A36 carbon steel angle bar good extrusion resistance, easy quality control and low cost features. Welcome to our company to purchase A36 carbon steel angle bar API 5CT N80 and so on casing pipes.

Our company has established and constantly improved the customer service system and emergency response system. Through the customer service management system, we track the service of the after-sales service team and provide efficient and standard services in time. At the same time, the company formulates a regular return visit system, compares the historical cases of customer problems, proposes a pre solution, and ensures that the service is in place in a short time.

Leave A Comment