The A573 Grade 58 carbon steel coil plate products have passed the EU CE certification, and have been recognized by China, France, the United States, the United Kingdom, Germany, Italy, Japan, South Korea and other eight classification societies for high-strength ship plates. The steel strand products have passed the United States (PTI) certification. The A573 Grade 58 carbon steel coil products enjoy a high reputation in the domestic and foreign markets. The products are applied to national key projects and sold to 37 countries and regions such as EU, Middle East, Southeast Asia and America.

S355J0 steel is a low alloy structural steel. We can supply S355J0 structural steel plates up to 400mm, with a minimum yield strength 355MPa when plate thickness less than 16mm, min. yield strength 345MPa when plate thickness range 16mm to 40mm. Without any special rolling or heat treatment for S355J0 steel plate and sheet, A573 Grade 58 carbon steel coil, the abbreviated designation of this delivery condition shall be AR (As rolled).

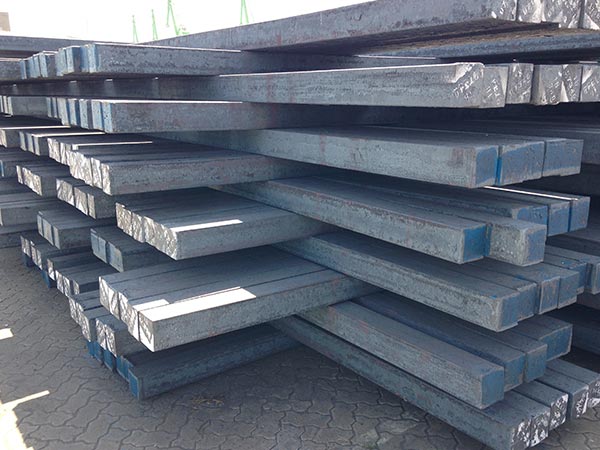

With equipment, technology, production technology, quality supervision and other leading advantages, we are leading in the production of all kinds of high-quality, high-tech medium, extra thick, extra wide steel plate A573 Grade 58 carbon steel coil shaped parts. The cutting surface is smooth and clean, the cutting edge is neat, without secondary processing by users, and it can be installed and used directly according to the technical dimensions, with the characteristics of high coincidence rate of positive and negative tolerance and excellent quality. The processed steel products are mainly used in heavy machinery and equipment.

The main function of boron in A573 Grade 58 carbon steel coil and so on steel is to increase the hardenability of steel, so as to save other rare and precious metals, such as nickel, chromium and molybdenum. For this purpose, the boron content is generally regulated in the range of 0.001% - 0.005%. It can replace 1.6% nickel, 0.3% chromium or 0.2% molybdenum. It should be noted that molybdenum can prevent or reduce temper brittleness, while boron slightly promotes temper brittleness, so molybdenum can not be completely replaced by boron.

A573 Grade 58 carbon steel coil, 15CrMo alloy steel is Chinese material. It is characterized by high Chrome and Molybdenum contents. The 15CrMo alloy steel chrome content is 0.80-1.10, and molybdenum content is 0.40-0.55. Besides, 15CrMo carbon content is 0.12-0.18, silicon content is 0.17-0.37, manganese content is 0.40-0.70. The heating temperatures for quenching and tempering of 15CrMo alloy steel are 900 and 650 centigrade respectively. The yield point of 15CrMo alloy steel is 295Mpa.

We are experienced shipbuilding and marine grade steel materials supplier and exporter with more than 20 years experience. For any question about the A573 Grade 58 carbon steel coil shipbuilding steel materials, such as shipbuilding steel price, ABS EH36 steel specification, Lloyds grade A steel properties, AH36 steel mechanical properties, AH32 steel price, DH32 steel dimensions, difference between EH36 and DH 36 etc., please feel free to consult us.

The company focuses on two markets at home and abroad, and has a group of 56 experienced sales elites and professional and technical personnel. It can provide customers with drawing design, A573 Grade 58 carbon steel coil deep processing services and installation solutions. 20 years of project experience has provided high-quality carbon steel, alloy steel products and high-quality after-sales service to customers in many countries around the world. The company has won widespread praise from customers.

Leave A Comment