In today's astm a572 steel market, most of the varieties are in excess of demand, especially after China's accession to the WTO, steel enterprises are facing increasingly fierce market competition. In order to make enterprises win a good surviva

In today's astm a572 steel market, most of the varieties are in excess of demand, especially after China's accession to the WTO, steel enterprises are facing increasingly fierce market competition. In order to make enterprises win a good surviva

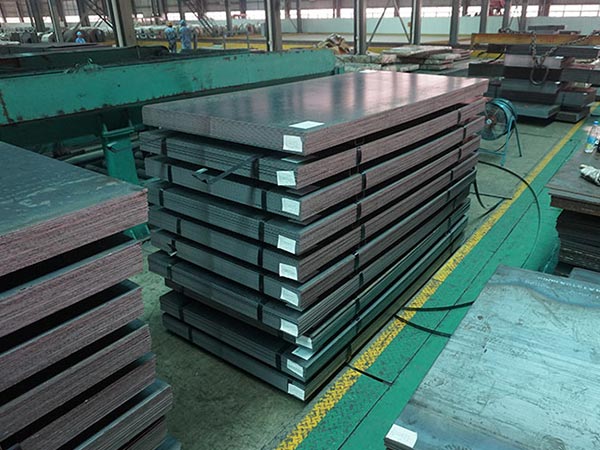

In today's astm a572 steel market, most of the varieties are in excess of demand, especially after China's accession to the WTO, steel enterprises are facing increasingly fierce market competition. In order to make enterprises win a good survival and development space, operators must make effective use of astm a572 market information resources to improve the scientificity of business decision-making and enhance the enterprises' domestic competitiveness Competitiveness in the external market.

The alloying elements of low alloy steel are less than 5%. The low alloy steel is added one or several alloy elements on the basis of carbon steel to improve the performance. Such as manganese, silicon, aluminum, nickel, copper, boron, phosphorus, rare earth, etc. astm a572 Steel with one or more of these elements will have the advantages of high strength and toughness. Due to the addition of few alloy elements, it is called low alloy high strength steel.

The wear-resistant layer of astm a572 wear-resistant steel plate is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium and nickel are added. The carbide in the microstructure is distributed in the form of fiber, and the direction of the fiber is perpendicular to the surface. The microhardness of carbides can reach hv1700-2000 and HRC58-62 respectively. The alloy astm a572 carbide has strong stability at high temperature, high hardness and good oxidation resistance. It can be used normally within 500 ℃.

The performance of heat treatment process reflects the difficulty of heat treatment and the tendency of defects of the steel. It mainly includes hardenability, superheat sensitivity, temper embrittlement tendency and oxidation decarburization tendency. The hardenability of astm a572, alloy steel is high. The cooling method can be used slowly during quenching, which can reduce the deformation and cracking tendency of the workpiece. The addition of Mn and Si will increase the superheat sensitivity of steel. The strengthening effect of alloy elements on steel in quenching and tempering state is the most significant.

"BBN STEEL astm a572 2020 newly inventory in Shanghai(500tons)16*1524*5900, 5*2800*12000, 15*2000*12000, 6*2500*12000, 10*2120*926012.5*1820*6096, 10*2900*7350, 24*2650*11100, 5*2800*12000, 8*2600*1000016*1524*5900, 8*2800*11230, 19*2910*11025, 32*2700*11025, 10*2270*711010*2120*9260, 65*2100*6000, 22.5*2910*11025, 12*2050*7780, 14*2050*90008*2600*10000, 10*2270*7110, 36*2140*9150, 40*2910*11000, 57*1600*6000

We are experienced shipbuilding and marine grade steel materials supplier and exporter with more than 20 years experience. For any question about the astm a572 shipbuilding steel materials, such as shipbuilding steel price, ABS EH36 steel specification, Lloyds grade A steel properties, AH36 steel mechanical properties, AH32 steel price, DH32 steel dimensions, difference between EH36 and DH 36 etc., please feel free to consult us.

In addition to quality assurance, service is also important for the competition of steel suppliers. All the after-sales service personnel of the company have received professional training and assessment. The steel products supplied by our company enjoy the life-long quality problem replacement service. In the process of using our steel astm a572 products, if there is any problem, just contact us in time, and our after-sales service personnel will look for countermeasures and solve the problem with you as soon as possible.

Leave A Comment