Our company's sa573gr.70 steel datasheet mild steel hot rolled plate power boilers, heating furnaces of double bars, double high lines and medium and thick plates all adopt heat storage technology, which can fully use blast furnace gas; the ladle baking, Maerz active lime kiln and medium and thick plate heat treatment furnace all burn converter gas, which can improve the sa573gr.70 steel datasheet mild steel hot rolled plate utilization rate of secondary energy and realize negative energy steelmaking in steelmaking process.

S960Q steel plate is a high-strength structural steel plate, which is mainly used to manufacture low-temperature-resistant, high-strength key components, construction machinery, and mining machinery structures. General construction and various engineering machinery applications, such as drilling rigs, electric shovels, electric wheel dump trucks, mining cars, excavators, loaders, bulldozers, various cranes, coal mine hydraulic supports and other mechanical equipment used in mining and various engineering constructions and other structural parts.

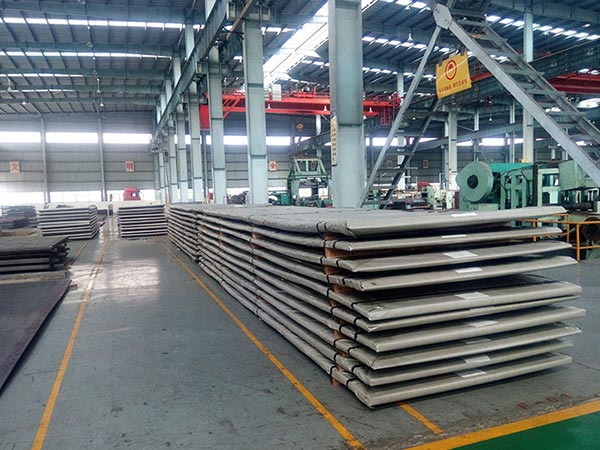

sa573gr.70 steel datasheet mild steel hot rolled plate, low alloy high strength steel has good atmospheric corrosion resistance and is widely used in engineering structure construction. Most of the engineering structures are used in the atmosphere or marine environment. A small amount of Cu, Ni, Cr, P and other elements are added to the low alloy high strength steel, which effectively improves the corrosion resistance of the engineering structure in the atmosphere, sea water and soil. If 0.2% - 0.5% copper, 0.05% - 0.1% phosphorus and aluminum are added, the corrosion resistance of steel can be improved obviously, and the effect of adding copper and phosphorus at the same time is the best.

sa573gr.70 steel datasheet mild steel hot rolled plate, Q390B steel plate generally adopts the process route of refined material entering the furnace-smelting (converter, electric furnace-microalloying treatment-argon blowing-LF refining-low superheat continuous casting (feeding rare earth wire)-controlled rolling and controlled cooling. During smelting, The scrap steel is added to the furnace along with the charge and smelted according to the conventional process. After tapping, the deoxidizer and alloy are added. After the molten steel is treated by argon blowing, it is cast immediately. Rare earth elements are added to the steel, the Q390B steel plate is purified, and the content of inclusions is greatly reduced.

P235GH steel material number under EN10028-2:2003 standard is 1.0345. This steel is a European pressure vessel steel. P235GH Mechanical properties: Tensile strength σb (350 ~ 480 MPa); Yield strength σs(215 MPa min.); Elongation ≥25%; Brinell hardness ≤105 ~ 140. sa573gr.70 steel datasheet mild steel hot rolled plate, P235GH steel chemical composition (mass fraction,%): ≤0.16 C; ≤0.35 Si; 0.60 ~ 1.20 Mn; ≤0.025 P; ≤0.010 S; ≤0.30 Cr; ≤0.30 Ni; ≤0.30 Cu; ≤0.08 Mo; ≤0.02 V; ≤0.02 Nb; ≤0.012 N; ≤0.020 Al; ≤0.03 Ti.

The strip steel thickness is generally below 6mm, which is convenient for crimping and processing. You should choose the sa573gr.70 steel datasheet mild steel hot rolled plate, strip steel specifications according to your own purposes. The specifications and materials used for different purposes are different, so you must confirm it before buying. It is best to ask professionals to give advice before purchasing strip steel, and purchase the specifications and types you need according to the corresponding requirements.

The company's after-sales service team is a high-quality professional team. Most after-sales employees have rich service experience and have reached the level of after-sales engineer. The after-sales department implements the after-sales personnel responsibility system and a 24-hour response mechanism. The company's advanced customer relationship management system provides customers with "standardized and streamlined services". A sound customer relationship maintenance system, and a "one-stop" customer satisfaction tracking system, all reflect our strong after-sales service guarantee.

Leave A Comment