The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our 10mm thick SA573 Grade 65 steel products are supplied in time, with reliable quality and perfect and thoughtful aft

The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our 10mm thick SA573 Grade 65 steel products are supplied in time, with reliable quality and perfect and thoughtful aft

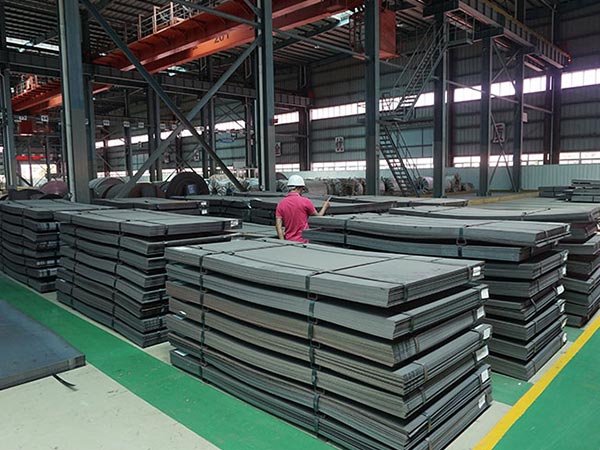

The company adheres to the service concept of "you give the order to me and I leave the satisfaction to you". Over the years, our 10mm thick SA573 Grade 65 steel products are supplied in time, with reliable quality and perfect and thoughtful after-sales service. Meanwhile, we have huge 10mm thick SA573 Grade 65 steel stocks all the year round. The company long-term pursues the principle of quality first, customer first, quality for survival, reputation for development, and perfect service to win the users.

The abrasion resistant 10mm thick SA573 Grade 65 steel plates, which also known as wear resistant steel plates, are among our main business scope. There are various abrasion resistant steel grades on the market. Among them, NM400, NM450, NM500, HARDOX400, HARDOX500, AR400, AR500, etc. are most popular. Meanwhile, NM400, HARDOX400 and AR400 are equivalent to each other. NM500, HARDOX500 and AR500 are also equivalent abrasion resistant steel materials.

Advantages of 10mm thick SA573 Grade 65, stainless steel: 1. Chemical properties: the chemical and electrochemical corrosion resistance of stainless steel is the best in steel, second only to titanium alloy. 2. Physical properties: stainless steel has good heat resistance, high temperature resistance, low temperature resistance and even ultra-low temperature resistance. Stainless steel can work safely at - 270℃ - 400℃ for a long time. No matter at high or low temperature, no harmful substances will be precipitated, and the stainless steel material properties are quite stable.

Alloy elements have the most significant strengthening effect on steel in quenched and tempered state. The primary purpose of adding alloying elements to steel is to improve the hardenability of steel and to ensure that martensite is easily obtained during quenching. The second is to improve the tempering stability of the steel to keep the martensite at a higher temperature, so that the carbides precipitated during the tempering of the quenched steel are finer, uniform and stable. In this way, under the same conditions, alloy steel has higher strength than carbon steel, 10mm thick SA573 Grade 65.

"We can supply carbon steel plate, 10mm thick SA573 Grade 65, hot rolled plate and structural steel sheet with high quality and various size. Thickness from 5mm to 300mmWidth: from 1,500mm to 2,500mmLength: from 6,000mm to 12,000mmTechnical conditions: Ultrasonic tested as per SA 578 or any other as per requirementMTC acc to EN 10204 / 3.2"

The company has a high-quality management, technology and R&D team, and adopts independent research and development, domestic innovative process optimization combination. Relying on advanced manufacturing technology and sophisticated production testing equipment, it has ensured the high quality of products 10mm thick SA573 Grade 65 and won a good reputation. We can offer various kinds of steel materials in GB, ASME, ASTM, JIS, DIN, EN, API standards and specifications.

Compared with other fast-moving consumer goods, steel consumption is obviously different, with a wide range of use and a long service life. Therefore, the quality and service of steel materials are particularly important. Service is always one of our top concerns, especially after-sales service. We have mature after-sales service team, and can help you solve problems professionally during application of the steel materials.

Leave A Comment