The bridge steel plate a572 alloy steel vs a656 alloy steel produced by BBN company has pure steel, flat and smooth plate surface, small difference between plates, -40 ℃ impact value and aging impact value are stable, and the margin is large. Bridge steel plates can be controlled by rolling, cooling, normalizing, and tempering organize production with different production processes. This bridge steel a572 alloy steel vs a656 alloy steel is widely used in the manufacture of large railway bridges and highway bridges.

Bridge steel plates are thick steel plates made of carbon steel and low-alloy steel for bridge construction. The main applications of bridge steel plates are to build railway bridges, highway bridges, and sea-crossing bridges. The bridge steel plates are required to have high strength, durability and bear the load and impact of rolling stock. Bridge steel plates have good water resistance, low thermal conductivity, flat and lubricated surface. The main grades of bridge steel plates are A709 grade 50, A588 grade B, a572 alloy steel vs a656 alloy steel and so on.

Non-destructive flaw detection of steel plates is a test method for inspecting the a572 alloy steel vs a656 alloy steel surface and internal quality of the inspected parts without damaging the working state of the workpiece or raw materials. Commonly used a572 alloy steel vs a656 alloy steel steel plate flaw detection methods include: X-ray flaw detection, ultrasonic flaw detection, magnetic particle flaw detection, penetration flaw detection, eddy current flaw detection, gamma-ray flaw detection, fluorescent flaw detection, color flaw detection and other methods. Physical flaw detection is non-destructive flaw detection without any chemical changes.

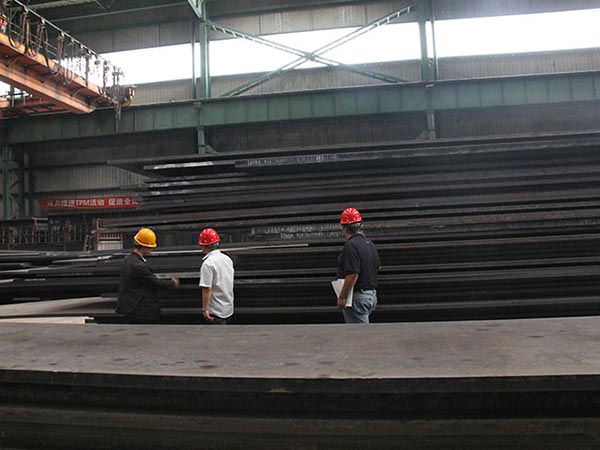

The company will rely on its good reputation, excellent hot-rolled plates, steel pipes, steel structure products, and intimate a572 alloy steel vs a656 alloy steel after-sales service to customers. I would like to express my heartfelt thanks to the old and new friends and customers who have always given care, support and help to the company! The company sincerely hopes to establish a long-term cooperative relationship with them, mutual benefit and common development. Welcome to come and visit our a572 alloy steel vs a656 alloy steel steel mill.

If customers have any difficult problems during use of the steel materials, they can contact the company's after-sales service department to feedback the existing problems. The after-sales department will reply as soon as possible to ensure that each customer has a good after-sales experience. Under special circumstances, the after-sales service department will start the problem-solving process, and the engineers in charge of the area will quickly follow up to solve the problem.

Leave A Comment