For the carbon steel structural tubing construction industry, the largest consumer sector of the steel industry and the least affected industry in the EU this year, it is estimated that carbon steel structural tubing steel consumption will account for 35% of the EU steel consumption market this year. Uestf forecasts that the output of the construction industry will decline by 5.3% in 2020 and rise by 4% in 2021.

Considering the large workload of allocation and transportion for our steel materials, we have built special shipping department, and make it independent form transportation department. The transportation department is in charge of transporting steel materials from our mill and warehouse to the port, and our shipping department is in charge of the shipping matters. So that our whole shipping efficiency is improved, and shorten time for customers to receive goods.

The yield point of the steel structure determines the stress that the structure can withstand without permanent deformation. The minimum yield point of typical carbon structural steel is 235MPa. The minimum yield point of typical low-alloy high-strength steel is 345MPa. Therefore, according to the proportional relationship of its yield point, the use of low-alloy high-strength steel allows the stress to be 1.4 times higher than that of carbon structural steel. Compared with carbon steel structural tubing, carbon structural steel, the use of low-alloy high-strength steel can reduce the size of structural parts and reduce weight.

The company uses outsourced logistics operations. Our cooperated professional third-party logistics providers use the advantages of large-scale production and cost advantages to achieve cost savings by increasing the utilization of resources in each link, so that we can benefit from the separation of cost structure. Therefore, we can also provide customers with better, faster and more efficient cargo transportation, delivery, and lower freight costs.

The sensitivity of high temperature tempering brittleness of wear-resistant plates is generally expressed by the difference between the toughness and brittleness transition temperature of the toughened state and the embrittlement state. The more serious the brittleness of high temperature tempering, the higher the proportion of the fracture surface along the grain of the wear-resistant steel plate, carbon steel structural tubing. The effect of the elements in the wear plate on the high temperature temper brittleness is divided into two aspects. One is the impurity elements that cause the high temperature temper brittleness of the wear plate.

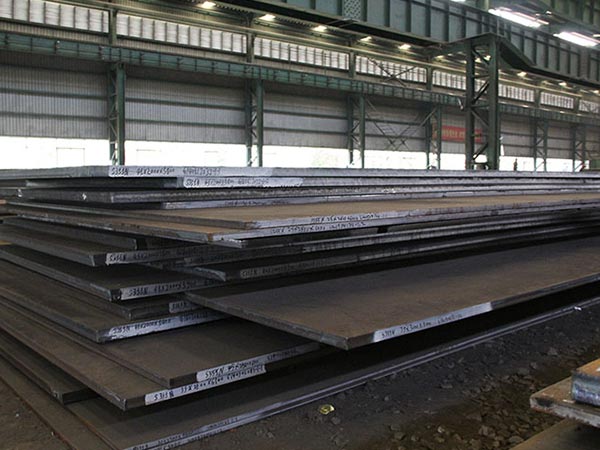

Welcome to our company to purchase, our products are exported to all parts of the world every month, the quality is guaranteed, the carbon steel structural tubing price is very preferential. Therefore, it has won great trust and praise from customers. Every month, it needs to purchase some steel plates, steel pipes and other major products. If you have any need, please contact us in time!

We should focus on the main problems to be solved and pay attention to efficiency. After receiving the user's quality objection report data, the possible causes, responsible units, compensation amount, etc. of the problem shall be judged based on experience. To have a clear service plan, to be clear about what your main problem is, what technical support is needed, these should be prepared.

Leave A Comment