Focusing on the energy conservation and emission reduction objectives proposed by the municipal government, the company gives full play to the advantages of high strength weldable steel plate circular economy formed after the comprehensive completion and operation, and vigorously promotes the implementation of energy conservation objectives. Through measures such as energy saving, technological innovation and high strength weldable steel plate management strengthening, the energy saving target of annual reduction of added value energy consumption by 7%. It has made great contribution to energy saving of over completion.

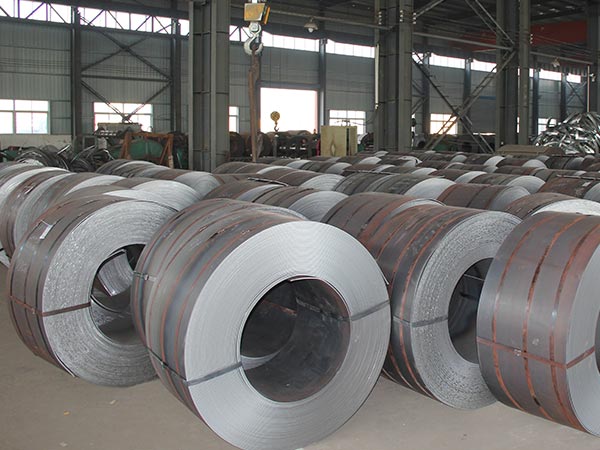

BBN company has steel plates production workshops and warehouses with a total area of more than 500,000 square meters, and the total inventory of various types of steel exceeds 1 million tons. Relying on world-leading processing equipment and storage facilities, the company has strong steel production and processing capabilities, comprehensive logistics and logistics services, ensuring that it can efficiently complete more than 1 million tons of hot rolled plates processing business each year.

There are many kinds of heat treatment processes for wear-resistant composite plate, high strength weldable steel plate, and they are applicable to different ranges. For example, direct quenching and low-temperature tempering can not refine the grain size of steel, the quenching deformation of workpiece is large, and the surface residual austenite volume of carburized parts of hardfacing wear-resistant composite plate is more, and the surface hardness is lower. It is suitable for gas carburizing and liquid carburizing.

The Indonesia INKA is the only train carriage maker for railway industry in Indonesia. We cooperated with them since 2012 and supply them SPA-H steel. The SPA-H steel is used by them to fabricate train carriage. We have huge stocks for SPA-H steel and can arrange delivery for them in short time after receiving order. Meanwhile, our product high strength weldable steel plate quality has passed their test for so many times use. Therefore, they trust us and give us repeat orders regularly. And we also do our best to support them and have never let them down though past cooperations.

Q295GNH steel chemical composition: C: 0.14~0.19, Si: ≤0.30, Mn: 1.00~1.30, P: ≤0.025, S: ≤0.025, Cr: 0.80~1.10Q295GNH mechanical properties:Tensile strength σb (MPa): 880-1180Yield strength σ0.2 (MPa): 635Elongation δ5(%): 9Reduction of area ψ(%): 35Impact toughness value αku (J/cm2): 34

The company operates on the principles of fairness, objectivity, science, pragmatism and integrity. The management treats people with courtesy, takes sincerity as the standard management, dares to open up, unites and advances, carries on the past and makes unremitting efforts, seizes the good trend of economic development, strengthens exchanges with peers, makes friends with all walks of life, keeps pace with the times and creates greater brilliance of the enterprise, and makes its own contribution to the prosperity and development of the steel industry.

Leave A Comment