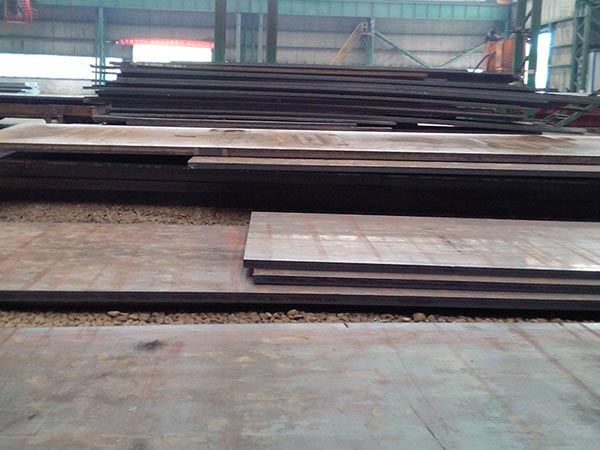

The company's main business: ship plate, astm a633 grade a low alloy plate, automobile steel, high-strength plate, pipeline steel, boiler steel plate, weathering plate, wear-resistant plate, bridge plate, pressure vessel plate, steel plate, steel processing, etc. The company takes the implementation of high-end, astm a633 grade a high-quality, deep processing, strengthening the main business, diversified operation, group operation, enterprise transformation and upgrading as its development strategy, and makes all efforts to be your professional astm a633 grade a steel supplier and partner.

The alloying elements of low alloy steel are less than 5%. The low alloy steel is added one or several alloy elements on the basis of carbon steel to improve the performance. Such as manganese, silicon, aluminum, nickel, copper, boron, phosphorus, rare earth, etc. astm a633 grade a Steel with one or more of these elements will have the advantages of high strength and toughness. Due to the addition of few alloy elements, it is called low alloy high strength steel.

40B steel plate is alloy structural steel plate formed by adding boron to the carbon structural steel with a carbon content of 0.40%. astm a633 grade a, 40B steel plate has high hardness, toughness and hardenability, and has good comprehensive mechanical properties after quenching and tempering, which can be used instead of 40Cr steel. 40B steel plate chemical elements: C: 0.37-0.44, Si: 0.17-0.37, Mn: 0.60-0.90, B: 0.0005-0.0035. 40B steel plate is used to manufacture parts with larger section and higher performance requirements.

Expression method of pressure coefficient of seamless steel pipe: pressure P < 7MPa coefficient S-8 7 < astm a633 grade a steel pipe pressure P < 17.5, coefficient 5-6 pressure P > 17.5, coefficient S-4 seamless pipe production and manufacturing: tube blank -- Inspection -- peeling -- Inspection -- Heating -- perforation -- pickling -- grinding -- lubrication and air drying -- welding head -- cold drawing -- solution treatment -- pickling -- pickling and passivation -- Inspection -- cold rolling -- degreasing -- air drying -- internal polishing -- one external polishing -- Inspection -- identification of finished astm a633 grade a product packaging.

42CrMo alloy steel astm a633 grade a: low temperature tempering welding performance thermal processingThe heating temperature is 1150 ~1200°C, the starting temperature is 1130 ~1180°C, the ending temperature is> 850°C, and when φ> 50mm, slow cooling. The normalizing temperature is 850~900°C, and the furnace is air cooled. High temperature tempering: Tempering temperature is 680~700°C, and it is air-cooled from the furnace.

It is very important for a company to have a sound after-sales service system, which better guarantees the interests of customers and increases the reliability of the company's products in the hearts of customers. Our company has a dedicated after-sales service team and good after-sales service reputation, and has been recognized by customers over the past decades. Whenever there is problem about our astm a633 grade a steel materials during application on the user site, our after-sales service persons will assist to find solutions at the first time.

Leave A Comment