The technology center has always been focusing on application research, improving market realization and scientific and technological contribution rate; taking user demand as the goal, highlighting the personalized development of products; taking the joint development of industry, University and research, and technology integration as the means, improving the starting point and level of innovation, and realizing the breakthrough of core technology; taking advanced research as the guide, pursuing the leap of technological development; taking system and mechanism innovation as the driving force, Promote and realize the working concept of technological innovation.

Among stainless steels, austenitic stainless steel has the best process performance. Due to its good plasticity, astm a656 grade 80 chemical composition, austenitic stainless steel can be processed into various plates, tubes and other profiles, suitable for pressure processing. Martensitic stainless steel has poor process performance due to its high hardness. Stainless steel has corrosion resistance, enhanced strength, steel deformation is not easy to crack and environmental protection performance, not easy to rust, and has good ductility and toughness. Stainless steel is suitable for use in harsh environments (indoor and outdoor environments such as humidity, acid and alkali).

Heat treatment process: heat treatment refers to a kind of process operation in which the metal or alloy can change the internal structure through certain heating, heat preservation and cooling methods in the solid range to obtain the required performance. astm a656 grade 80 chemical composition Heat treatment process refers to the ability to change the microstructure and properties of astm a656 grade 80 chemical composition after heat treatment, including hardenability, hardenability, temper brittleness, etc.

Hot Rolled Plates astm a656 grade 80 chemical composition MachiningAfter final forging/forming and Heat treatment process, all the pipe Fittings, Flanges, Fasteners, Etc. are sent for machining i.e. and preparation, O/D and I/D matching as per dimensional codes. An Expert Q.C. engineer is involved and he keeps constant vigil on every machining operation. Step machining is carried out as required by the codes. GO and NO-GO gauges are used to check the O/D & I/D of the fittings, Flanges, etc.

The company's logistics adopts the method of cooperation with logistics companies. As a third-party logistics company is engaged in the operation of multiple logistics projects, it can integrate various logistics resources, making the logistics operation cost relatively low and the logistics operations more efficient. Thus we can provide more professional logistics services, while also focusing on our core business of steel materials.

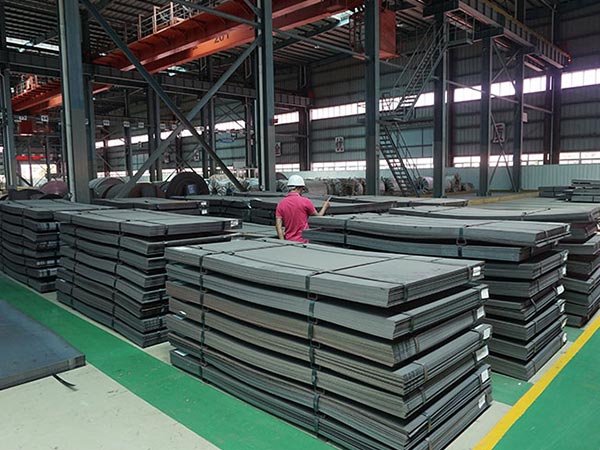

The company specializes in hot rolled plates producing, steel plate processing, steel plates cutting, carbon steel plate weldding and exporting of wide and thick steel plates. BBN company has high-quality CNC astm a656 grade 80 chemical composition steel plate cutting processing equipment, professional technical personnel, and supporting marketing and after-sales service system. Sincerely welcome new and old customers to visit our company, BBBN company will always be your reliable choice.

Leave A Comment